This video contains proprietary information and cannot be shared publicly at this time.

Figure 1

Figure 2

Team 14

Team Members |

Faculty Advisor |

Joey Radcliff |

Kristina Wagstrom Sponsor UConn School of Engineering |

sponsored by

Sponsor Image Not Available

Modular Distributed Gas-to-Liquids (GTL) Synthesis

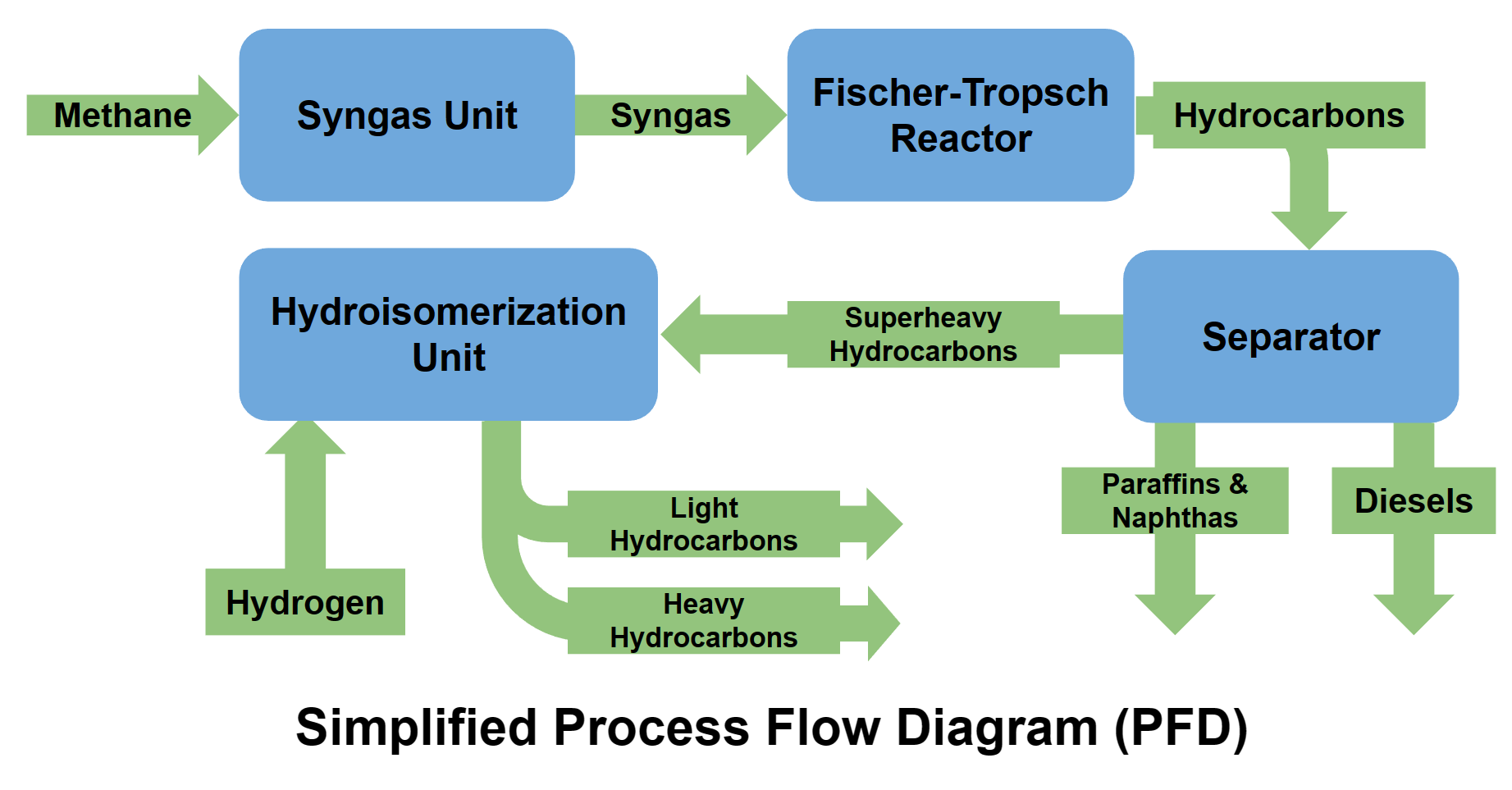

Extracting oil deposits releases associated natural gas, but occasionally the cost of harnessing this gas outweighs the potential profits of selling the gas. This is due to conditions at a specific oil well such as geographic isolation or local regulations. In this case, the natural gas is combusted and released into the atmosphere in a practice called “flaring.” However, flaring produces pollutants such as carbon dioxide that contribute to negative environmental consequences, like climate change. According to the World Bank, 3.6% of natural gas produced annually is flared. This project focuses on Gas-To-Liquid technologies which convert natural gas into a storable, economically recoverable, liquid form. Our solution uses the Fischer–Tropsch Reaction (FTR), which converts methane into large hydrocarbons that are liquid at room temperature. These liquid hydrocarbons are then separated into relevant fuel types. The design of our FTR and separator units is modular. This allows them to be scaled to different input volumes of natural gas and moved between sites. The implementation of our design would make it more viable to collect natural gas at challenging sites by removing challenges associated with storing and transporting gases, such as the necessity of pipeline infrastructure. By making collecting associated natural gas economically appealing to companies that still practice flaring, this design can help reduce global emissions.