This video contains proprietary information and cannot be shared publicly at this time.

Figure 1

Team 44

Team Members |

Faculty Advisor |

Adam Franzen |

Vito Moreno Sponsor Pratt & Whitney |

sponsored by

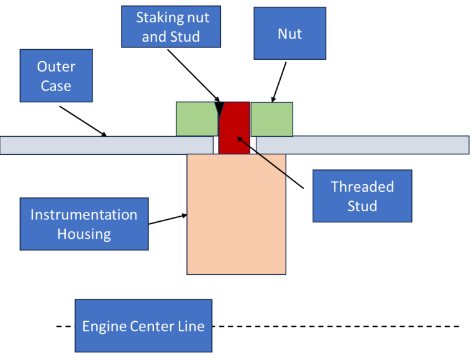

Vibra-staking For Anti-Rotation of Delicate Threaded Joint

This project is based on a new staking method created by Pratt & Whitney. Aerospace engines undergo various types of testing, including vibration tests, deflection tests, temperature tests, and pressure tests. The instrumentation used to conduct these tests is typically attached to the engine case and exposed to vibrations. Staking a threaded connection to prevent the loosening of the nut due to vibration is a highly robust method that requires minimal effort. However, traditional staking, which involves a hammer and a hammer punch, can subject the threaded stack to a high impact load, potentially damaging some of the delicate instrument components. In this project, instead of using a hammer, an engraving tool will be employed to perform the staking. The engraving tool can be adjusted to reduce the amplitude of the stroke, resulting in a very low impact force that won't harm any instrument components. The objective of this project is to develop and demonstrate a repeatable process for using an engraving tool to secure locking nuts without damaging the underlying instrumentation components. Overall, using the method of vibra-staking can significantly improve the company's ability to obtain more reliable data during engine testing and provide a new method of staking threaded joints.