Figure 1

Figure 2

Mechanical Engineering

Team 4

Team Members |

Faculty Advisor |

Chandler Boucher |

Jason Lee Sponsor Belimo |

sponsored by

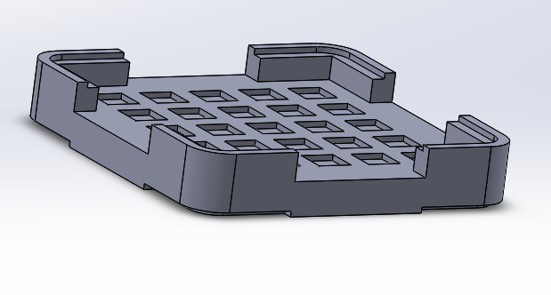

Belimo is a Swiss-based manufacturer and distributor of actuators, sensors, and control valves for heating, ventilation, and air conditioning systems. The MTO (Made To Order) Linkage department at Belimo’s Danbury, CT facility is exploring the implementation of a collaborative robot into their assembly processes to improve their overall efficiency and quality. It was identified that the manual sub-assemblies for linkages would see the most improvement through automation as they are relatively simple, produced in high quantities, and are time consuming. Our team is tasked with studying the feasibility of implementing a co-bot into these sub-assemblies. One of the main challenges for this project is ensuring proper part orientation as visual aid software is not feasible. Our team decided that palletizing the parts before presenting them to the co-bot ensures proper orientation with high repeatability and stacking them within the co-bot’s reach allows for longer periods of operation before downtime. The completed co-bot workspace design has improved the overall efficiency and quality while reducing the time needed to complete the chosen assembly processes.