Team 25

Team Members |

Faculty Advisor |

Connor Glassel |

Alexandra Hain Sponsor UConn School of Engineering |

sponsored by

Sponsor Image Not Available

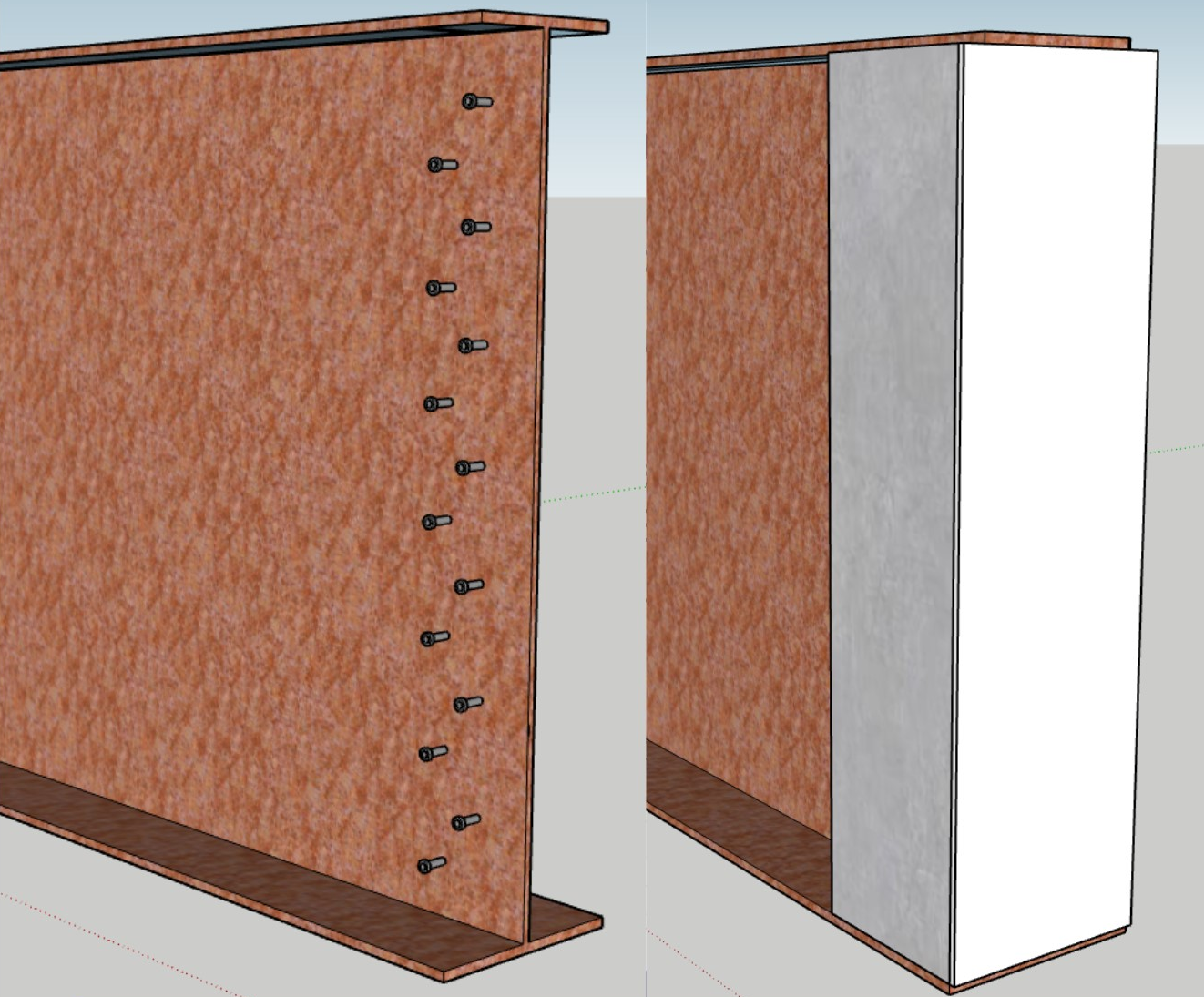

Degradation of beam ends on simple span steel bridges is a recurring issue for the Connecticut Department of Transportation. Corroded beam ends present safety concerns for the travelling public as section loss reduces the capacity of the beams, and is costly to repair. To mitigate these costs, bridge designers have begun gravitating towards maintenance free designs. This project primarily focuses on the viability of Ultra High Performance Concrete (UHPC) encasement as an efficient alternative for the design and construction of maintenance-free steel bridges. In this design, a UHPC bearing column replaces the typical steel bearing stiffener. UHPC is used to encase the beam ends over bearings and shear studs welded to the web, transfer the load from the beam to the UHPC column, and finally to the bearing. A traditional bearing stiffener design using AASHTO LRFD was compared to a UHPC encased design using the UConn guidelines for beam end encasement for a sample single span bridge. To obtain unfactored loads and assess necessary demands, LRFD Simon was utilized . With the final design complete, the team will perform a cost analysis of the encased design compared to currently used methods to reduce corrosion including weathering steel, galvanization, and metalization.