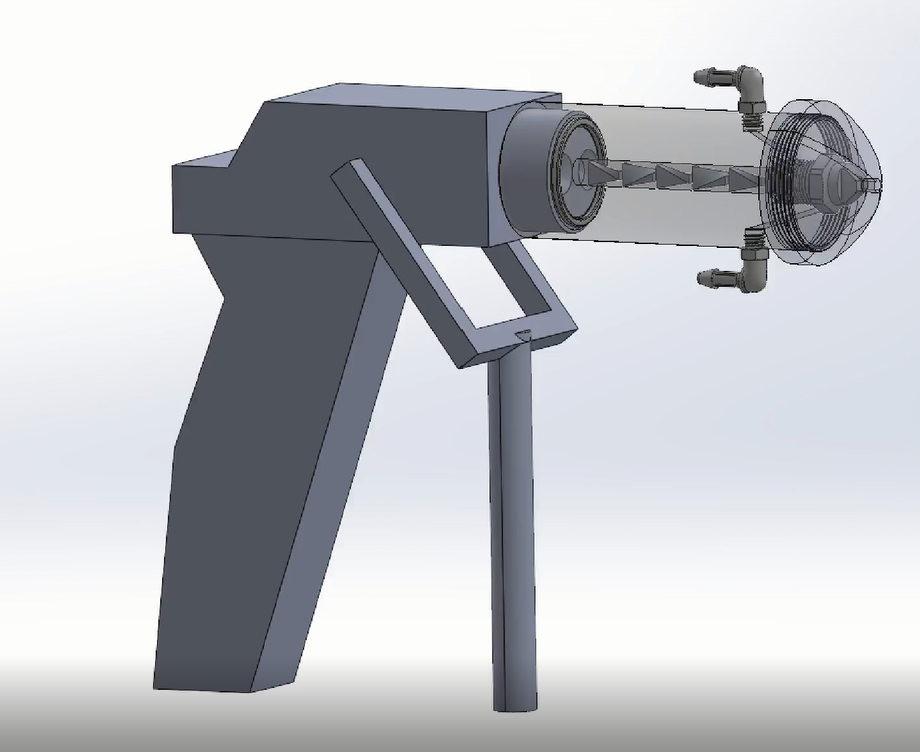

Figure 1

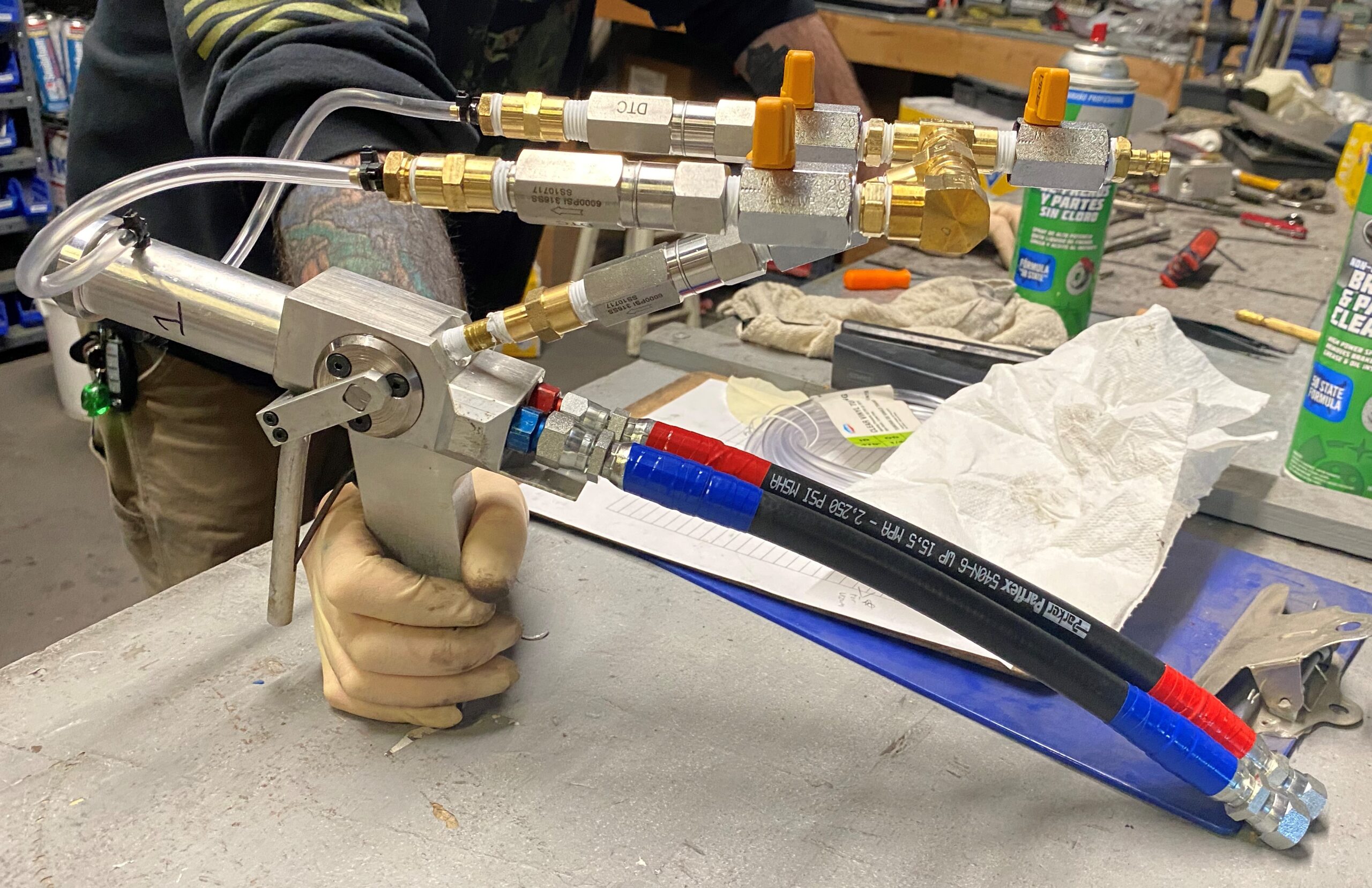

Figure 2

Team 1

Team Members |

Faculty Advisor |

Jacob Tran |

Francesco Carbone Sponsor Acme |

sponsored by

The objective of the project was to research and design a low-cost, disposable foam spray gun continuing off ACME Machinery’s initial prototype. If successful, it would be introduced into the future spray foam gun market. Spray foam guns have an input of two chemicals, isocyanate and resin. When mixed in a 50:50 ratio, the solution rapidly expands to form polyurethane foam, creating superior insulation for homes, commercial and industrial buildings. For ease of application, spray foam guns typically use compressed air to atomize and spray the foam, as well as incorporate a purge system to cleanse the gun of leftover chemicals and prevent clogging. Our spray foam gun had to operate at low-pressure and high-pressure between 120 psi and 1400 psi, respectively, for use for a homeowner and commercial environment, as well as have a comparable flow rate and spray pattern to current guns on the market. Current guns in the market can cost around $3,000 because of the multiple components involved and constant maintenance so our challenge was to reduce the amount of components to make a simplistic gun for a low price point of $100. Issues with ACME’s initial prototype included improper mixing, no spray atomization, and lack of knowledge of the air purge system. The ME 01 team has come up with a design using Computer Aided Design and Computational Fluid Dynamics modeling to address these issues. After having our design machined, we planned and performed various spray tests to determine the effectiveness of our design with and without air assistance. With these tests we were able to come up with an iterative design to further meet our goals of simplicity and low cost.