Figure 1

Figure 2

Team 50

Team Members |

Faculty Advisor |

Zoë Coleman |

Vito Moreno Sponsor Rubber Labels |

sponsored by

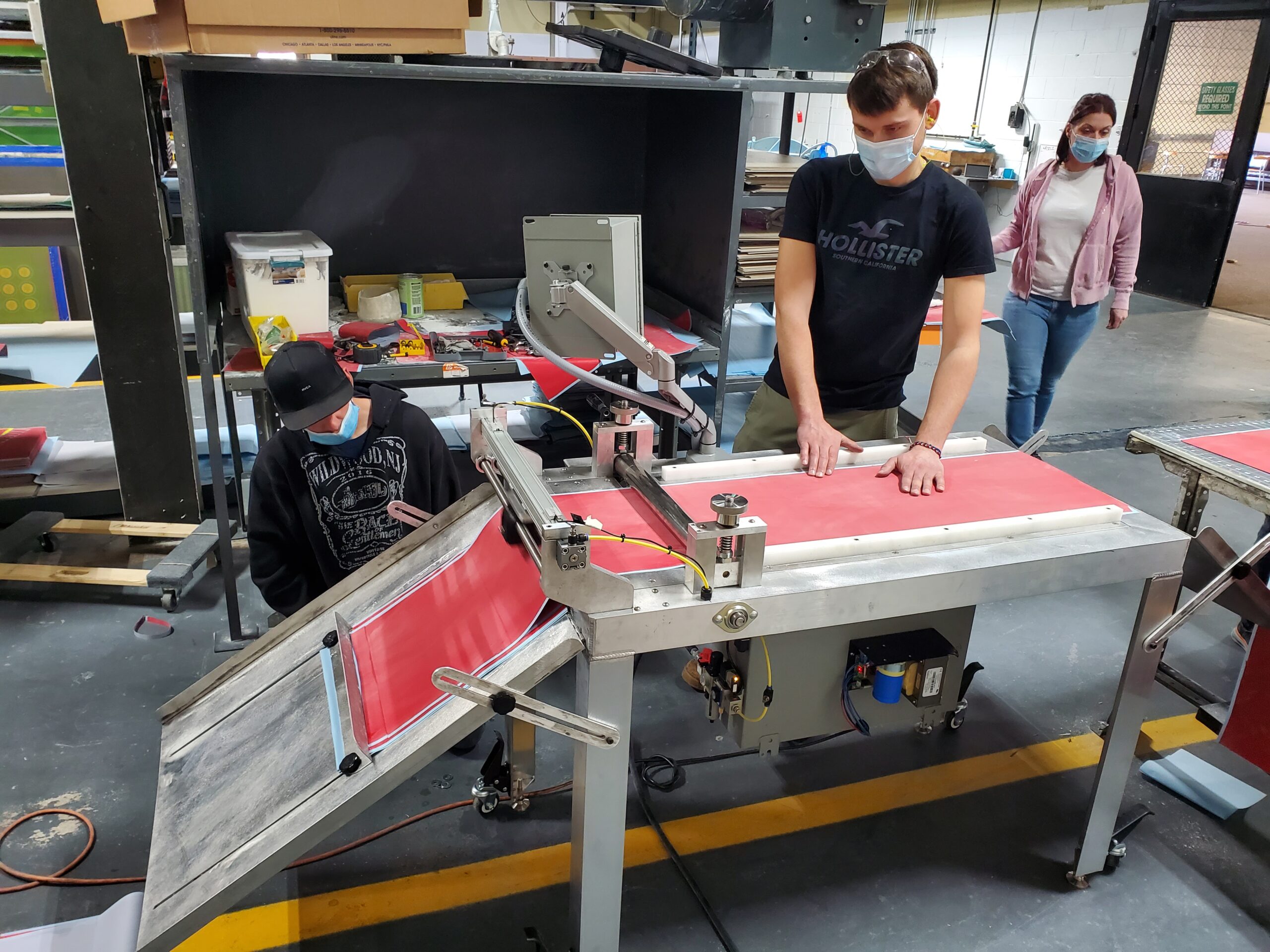

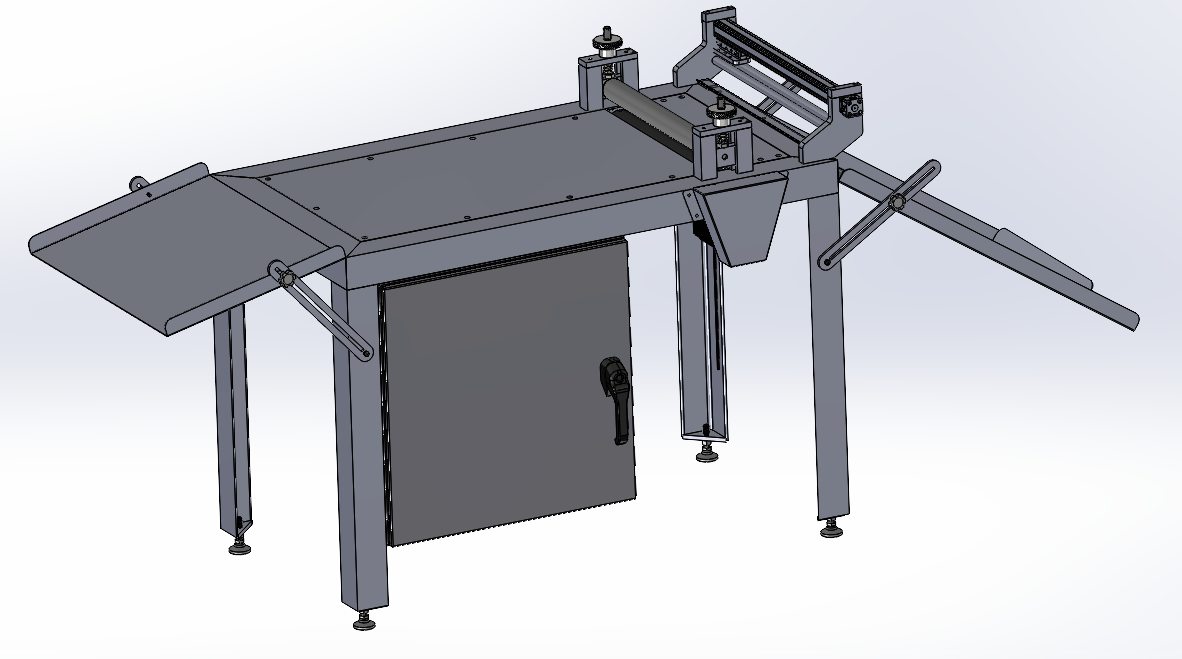

Rubber Labels USA is a local family run business in Milford, CT who manufactures vulcanized silk screened rubber labels used in applications such as PPE, footwear, tire sidewalls, and more. Their current process requires three operators to produce calendered sheets of rubber. The first two operate the calender’s feed and exit while the third performs post processing operations. In post processing, a layer of corn starch is applied as an anti-tack to prevent sticking. Then, rubber is measured and finally sheets are cut to length and stacked. The objective of this project is to design, develop, and build an automated rubber post processing rig for Rubber Labels USA. This machine will replace the need for a third operator in order to make the manufacturing process more efficient, cost effective, and less labor intensive. In order to fulfill the role of the third operator, the machine will include a feed rolling system, cutting system, and stacking exit chute. The rig is controlled by a PLC and ladder logic program. Interaction with the machine and its parameters is done through an HMI touch screen and its control panel. With our final design, the rubber sheet is pulled between two guides through a pair of spring loaded pinch rollers driven by a stepper motor. The sheets are fed to their desired length by counting the steps per revolution on the stepper motor. After the sheets have been fed to length they are cut using a shearing style cutter. The cutter, driven by a rodless pneumatic cylinder, rides against a hardened metal knife providing a consistent cut to the rubber. The cut sheets then exit the machine via a chute with an adjustable stop, allowing for neat stacking.