Figure 1

Figure 2

Team 59

Team Members |

Faculty Advisor |

Luke Vancraeynest |

Nejat Olgac Sponsor Other |

sponsored by

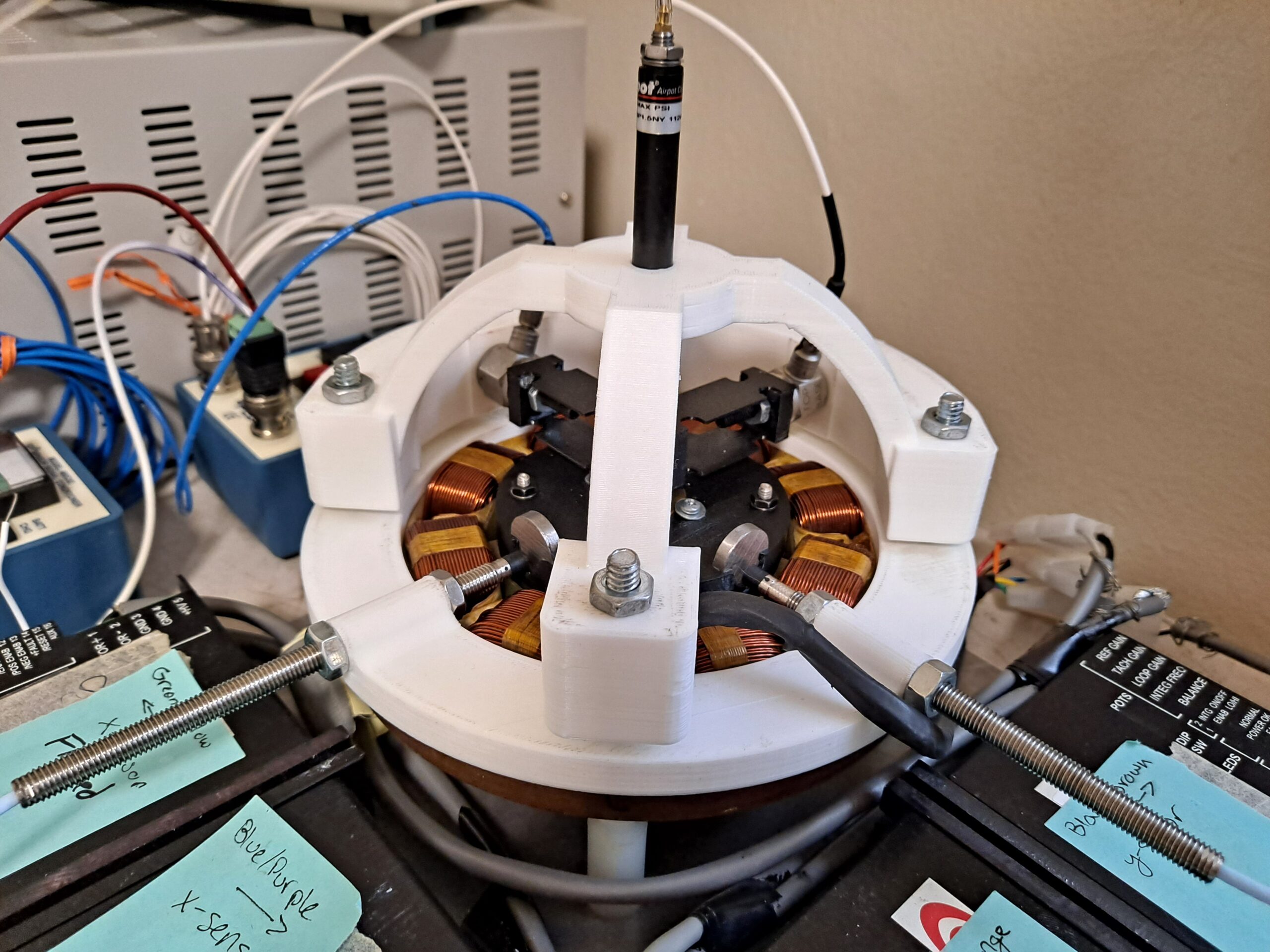

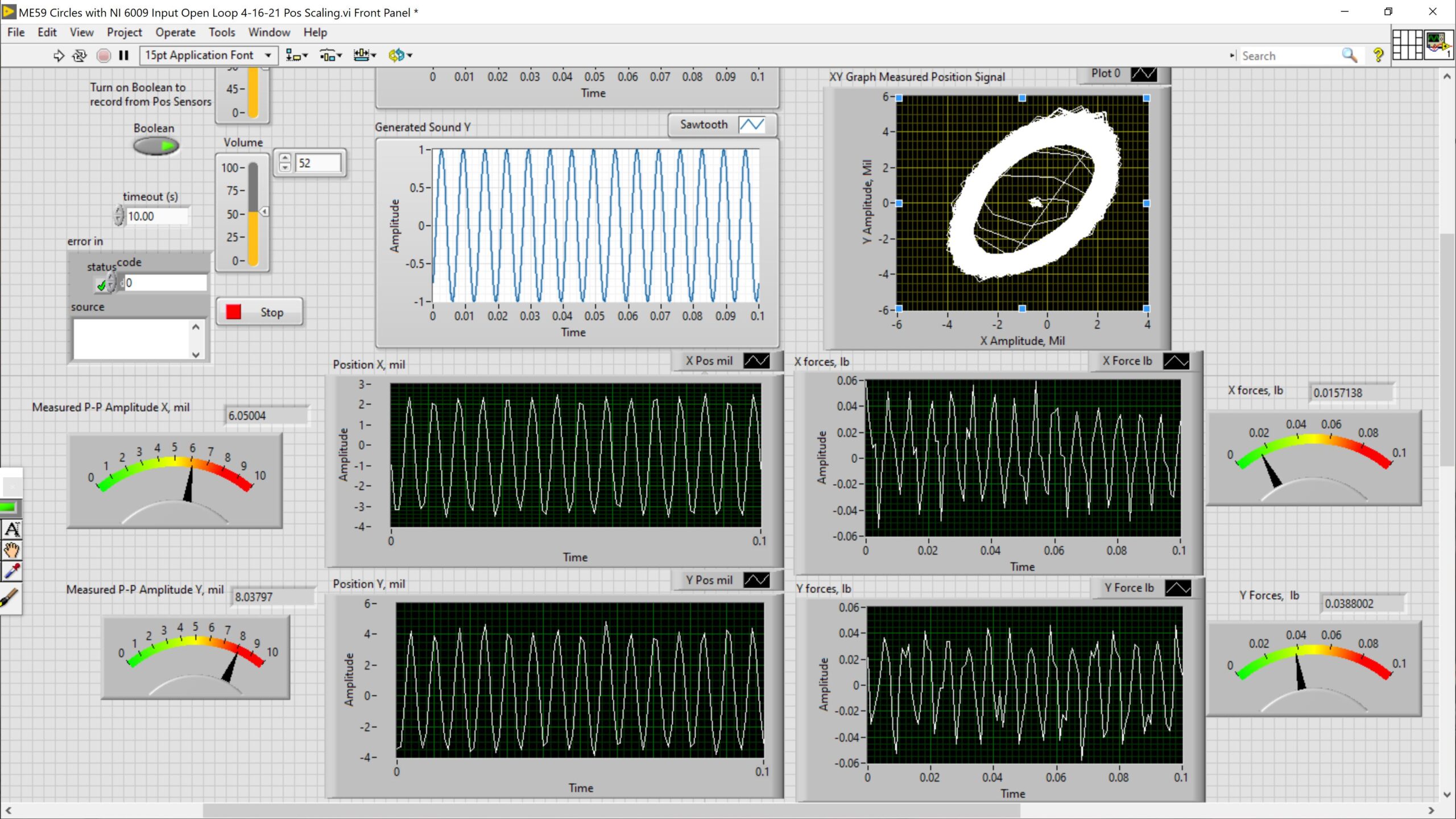

The purpose of this project is to continue improving upon the existing test rig prototype from last year’s team ME60. The requirements of the test rig are to represent low amplitude (10 mil), high frequency (up to 1000 Hz) controlled wear patterns such as a circle on a test specimen, while also applying a vertical load on the test specimen. The test rig consists of a magnetic bearing which creates a magnetic field to control the movement of a center core piece in user defined wear patterns. A LabVIEW VI sends signals to external soundcards, which further send the signals to amplifiers to control the power of the magnetic bearing’s coils. This LabVIEW VI is capable of changing the frequency and amplitude of the desired signals, as well as the desired wear motion pattern of the core. The VI also measures the movement of the core and plots this as a comparison to the desired wear motion patterns. A 3D printed platform is fastened into the core, upon which a material sample is mounted. The vertical load applicator frame includes a 3D printed test specimen holder. The test specimen holder is depressed by way of a pneumatic actuator, thereby pressing the specimen against the material sample it will wear against during testing. Load cells connected to the specimen holder measure the forces experienced by the test specimen when the core is in motion, while position sensors measure the motion of the core within the magnetic field.