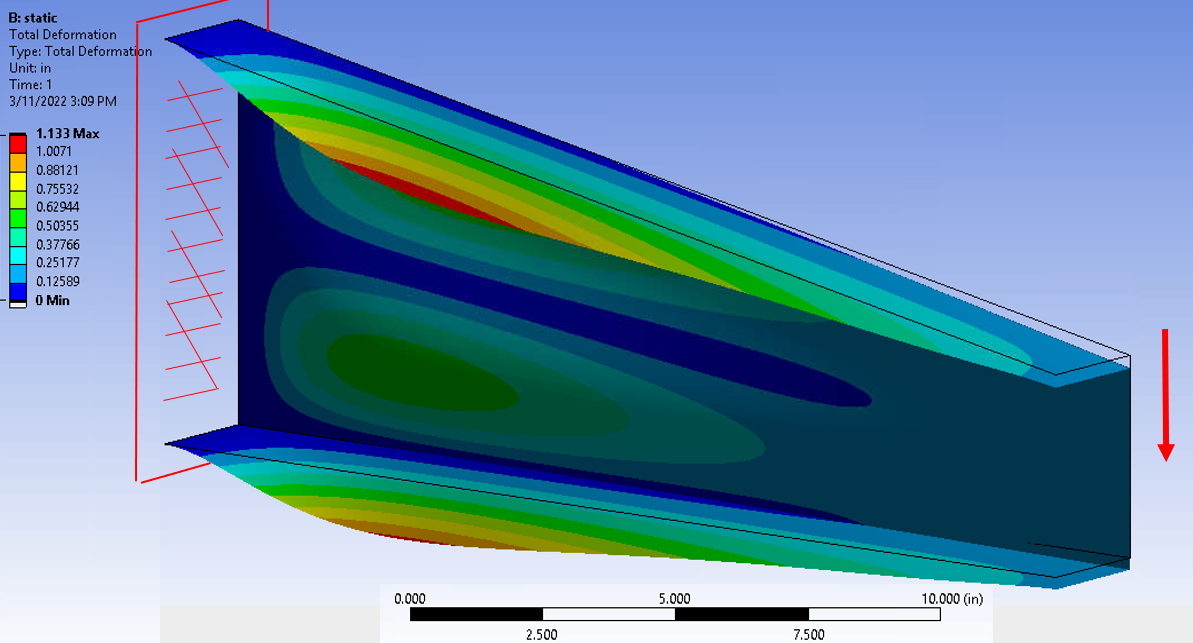

Figure 1

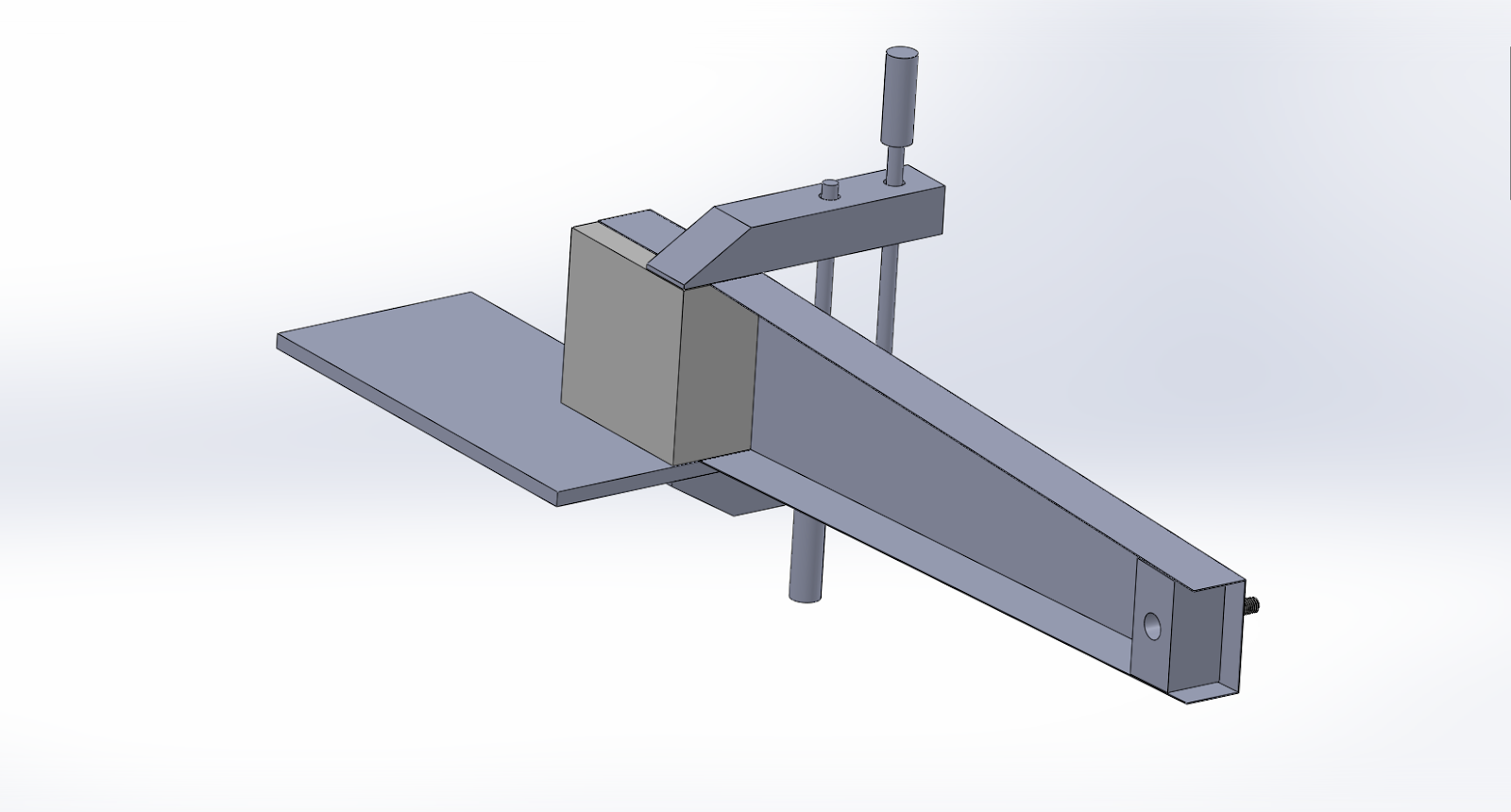

Figure 2

Team 52

Team Members |

Faculty Advisor |

Austin Huang |

Rajiv Naik Sponsor Sikorsky Aircraft Corporation |

sponsored by

Design and Validation of Tapered Composite C-Section Beam Structures

C-Beams are commonplace in engineering structures. This shape is notable because the basic shape can provide high bending stiffness in one direction, but offers a relatively compliant member when subjected to twisting loads along its length. Using composite materials, the disparity between bending stiffness can be increased for a C section. These structures are used in the aerospace industry, for example in helicopter rotor applications. The objectives of this project are to design, analyze, fabricate, and test tapered C-Beams to identify viable design configurations for helicopter rotors. In order to achieve these objectives, different C-Beam structures were analyzed using Finite Element Analysis. Composite C-Beams with varying tapered angles and layups were fabricated and tested to investigate the effects of loading, taper angle, and composite layup on the overall stiffness and compliance. As a result of this research project, the team was able to provide Sikorsky Aircraft Corporation with a validated composite C-Beam design methodology.