ME57: Laser Welding Fixture Improvements

The Team:

Audrey Rivetta

Ishu Joshi

Fig. 1 The Team |

|

Faculty Advisor:

Georgios Matheou

Sponsor Advisor:

Brandon Kumnick |

|

Overview:

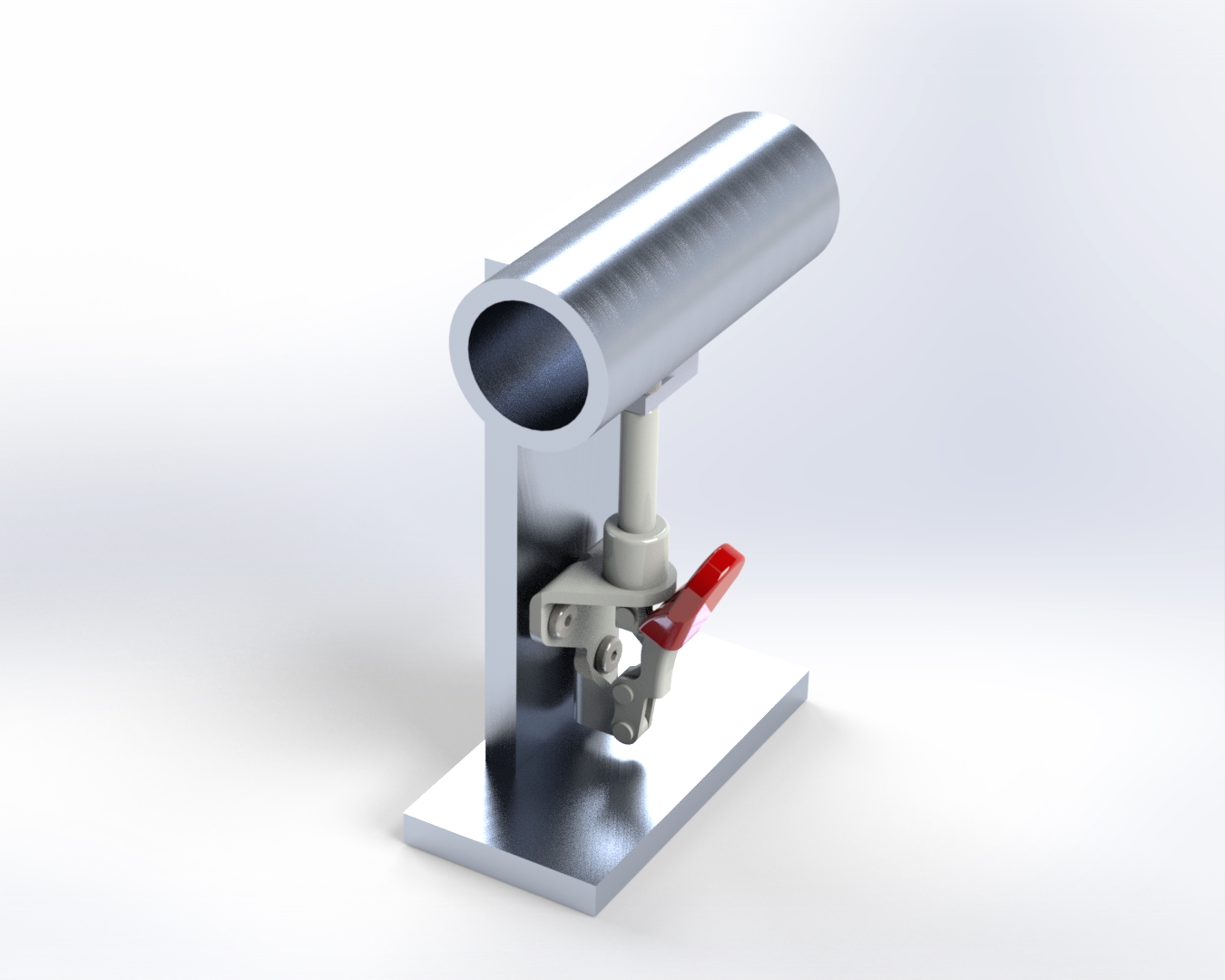

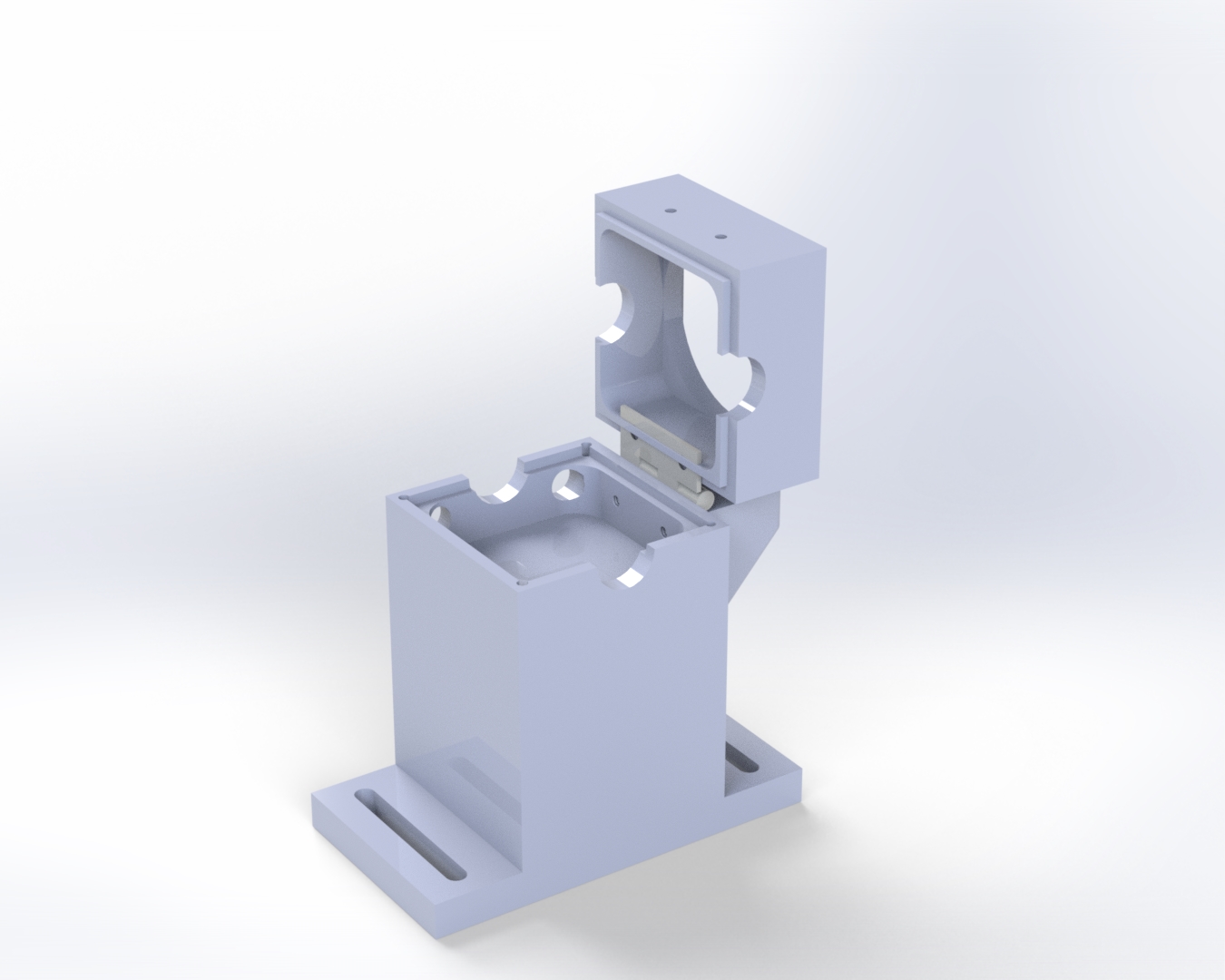

The goal of this project is to redesign a welding fixture for TOMZ corporation in order to reduce the cycle time and decrease the amount of argon consumed per cycle. Achieving these goals will increase the production rate of a critical part at TOMZ as well as reduce the cost of each part. Currently, during the welding procedure, TOMZ corp. fills the chamber (Fig. 3) with argon and laser welds two components together. After analyzing different shapes, the team circled in on the new geometry of the chamber (Fig. 2). Along with the redesign in the interior of the chamber, the team also reestablished the process of the alignment of the two sub components, decreasing the cycle time of the process.

Fig. 2: New Argon Chamber |

Fig. 3: Current Argon Chamber |