This video contains proprietary information and cannot be shared publicly at this time.

Figure 1

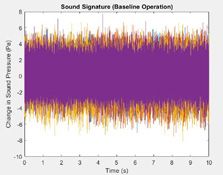

Figure 2

Chemical and Biomolecular Engineering

Team 5

Team Members |

Faculty Advisor |

David Carelli |

George Bollas Sponsor Gerber Technology |

sponsored by

Gerber Technology (Tolland, CT) is a leader in automated materials cutting for the apparel, graphics, furniture, and aerospace industries. The goal of this project was to streamline fault diagnosis in these automated machines by using signal processing techniques. The sound signatures of an automated cutting machine at various faulty operating conditions were modeled and compared to faultless operating conditions of the machine. The Fourier Transform was applied to the system to translate the collected sound data to its constituent frequencies. Principle component analysis (PCA) was then implemented to reduce the data size and identify signal intensities and peak frequencies that were specific to each operating condition. The classification function of k-nearest neighbors (KNN) was then trained with the data that was analyzed through PCA. After the algorithm was properly trained, KNN was able to compare unknown sound signatures to the known data, labeled as either baseline (faultless-operation), loose knife, no knife, or no belt (faulty-operating conditions) to identify the operating condition they are correlated to. Implementing this fault-feature extraction system into the machines allowed faulty-operation to be resolved more efficiently than guess-and-check resolutions; resulting in safer-repair of the machine, as well as time and money saved by the company.