Figure 1

Figure 2

Chemical and Biomolecular Engineering

Team 6

Team Members |

Faculty Advisor |

Christina Cokely |

Anson Ma Sponsor Unilever |

sponsored by

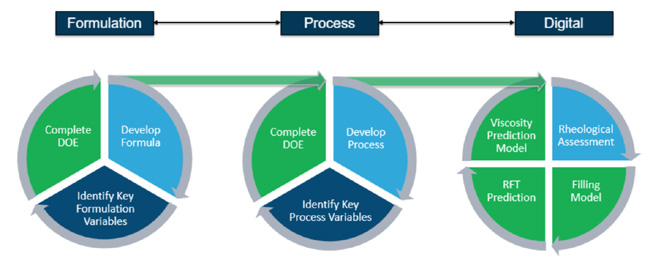

Recently, Unilever has developed multiple digital models and tools to help streamline product and process design; however, the company lacks a standardized method utilizing these tools. The goal of our project was to implement these digital tools to create an end-to-end procedure for product and process design using Dove Body Wash as a case study. Our team formulated 21 lab-scale batches as part of a Design of Experiment (DoE) to identify which ingredients most impacted the final properties of the body wash. The data was processed using statistical software to simulate 5,000 factory-scale batches and subsequently predict the main ingredient drivers. This prediction served as the basis for the experimental work performed in the pilot plant. A consolidated DoE at the bounds and center of the formulation space was conducted to assess potential impacts the process had on the product. Then, models predicting quality and run conditions at the factory were created. This method will facilitate digitally enabled product development and will streamline screening of formulations, reduce project timelines and limit over expenditure of time, money, and manpower all while creating a more sustainable business. Implementation of this standardized method will advance Unilever’s ability to consistently deliver high-quality products to the 2 billion consumers who use their products every day.