Figure 1

Mechanical Engineering

Team 1

Team Members |

Faculty Advisor |

Cara Connors |

Thomas Mealy Sponsor AeroCision LLC |

sponsored by

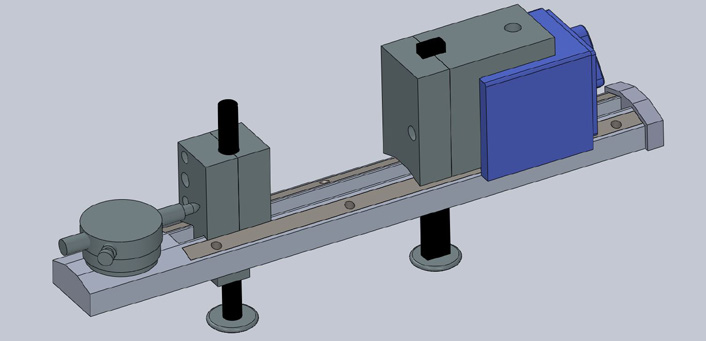

This project presents the research, design, and fabrication of a cost effective and time efficient diameter measuring gage for AeroCision LLC. AeroCision is a supplier of machined metal engine components for the aerospace industry based out of Chester, CT that emphasizes quality and precision in all of their facilities. The previous diameter measuring solution was a set of expensive purchased gages of different size ranges that measured diameter dimensions called out on customer component prints. This project’s swing gage is one product that is adjustable within 2-20” inner and outer diameter measurements to replace the set of purchased gages. The re-designed swing gage reaches the goal of costing 25-33% of the previous models, has ? of the previous calibration time, and maintains an accuracy within 0.0001”. The manufactured product passes gage repeatability and reproducibility testing without marring component surfaces and the thermal structural simulations prove its competency within working environments between 65 and 80 degrees Fahrenheit. The design uses a combination of clamping, spring, and magnetic forces to perform measurements and maintain accuracy in conjunction with a dial indicator to record the reading.