This video contains proprietary information and cannot be shared publicly at this time.

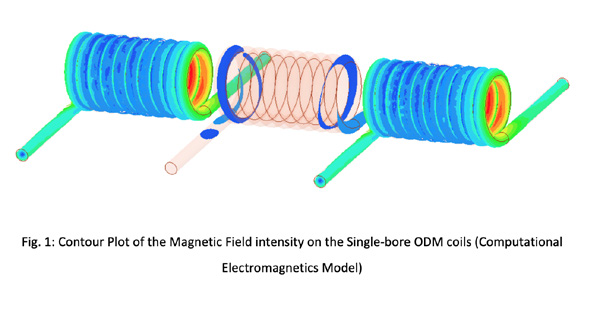

Figure 1

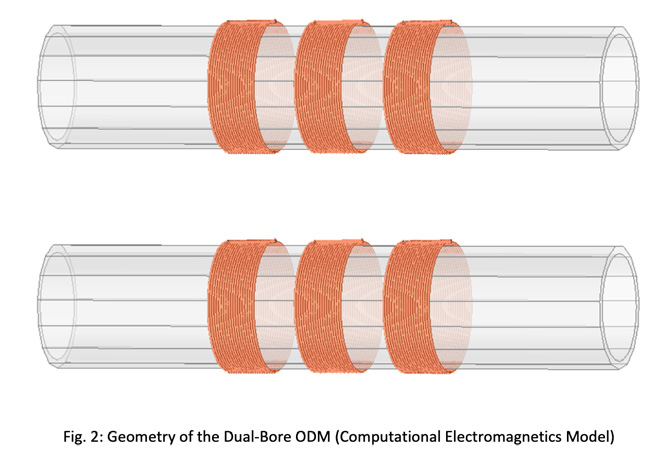

Figure 2

Mechanical Engineering

Team 25

Team Members |

Faculty Advisor |

Gursimran Kainth |

Julian Norato Sponsor Pratt and Whitney |

sponsored by

The objective of this project is to model and prototype a dual-bore Oil Debris Monitoring (ODM) system for use in Pratt & Whitney’s engines. The ODM sensor detects debris particles in engine oil and helps prevent engine failure. The current ODM used by P&W consists of a single assembly in which the pressurized lubricant flows through a single channel to one sensor. The proposed dual-bore ODM minimizes electromagnetic interference between the interacting coils’ magnetic fields while optimizing the sensor’s ability to detect small particles with high accuracy while remaining operable with a split flow path. ANSYS Maxwell and Fluent are used to model the electromagnetic and fluid properties of the dual-bore ODM, respectively. Maxwell model iterations are tested and analyzed with respect to varying coil properties and debris particle placement. Results show that under tested operating conditions, neighboring ODMs could be placed within close proximity with minimal magnetic field interference. The current running through sensing coil (dictates the sensor’s ability to detect debris particles) increases when a particle is present. Fluent model iterations are simulated with a single and split flow path to verify operable flow behavior and pressure conditions.