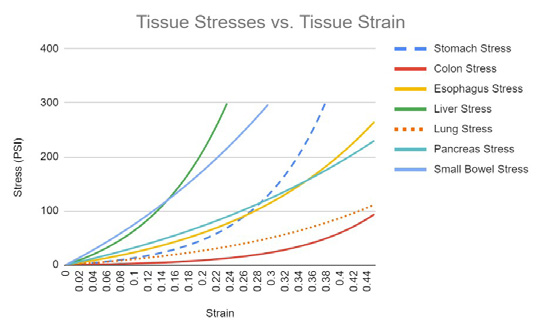

Figure 1

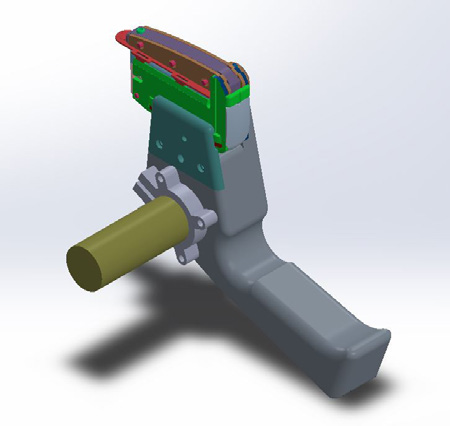

Figure 2

Mechanical Engineering

Team 30

Team Members |

Faculty Advisor |

Devon Casazza |

Thanh Nguyen Sponsor Medtronic |

sponsored by

Medtronic is a global leader in medical device design that creates devices to assist in surgery and patient recovery. ME 30 was tasked to design and build a handheld compression test device capable of determining the material properties of tissue. This project focused on fixing the design issues of their existing prototype. ME 30 updated the drivetrain of the device to allow the use of a single motor to achieve different linear clamping speeds, replaced the existing strain gauge with a force sensor to allow for accurate measurement, and redesigned the packaging to allow the electronics to be housed within the handle of the device. This device will be used to create a database of tissue properties that will be used to inform surgical stapling procedures. To design the prototype, elementary mechanical design equations were used to update the existing gear train design and choose a new motor. A miniature compression load cell was chosen to measure the stress-strain properties of the tissue sample. All components are internalized in a 3-D printed handle. To validate the prototype, testing was completed at UConn and on-site at Medtronic with a material with known characteristics. Comparing the results from the prototype with the data from the device allowed the design to be validated. This project is a joint project with ECE.