Figure 1

Figure 2

Mechanical Engineering

Team 42

Team Members |

Faculty Advisor |

William Broding |

Nejat Olgac Sponsor Pratt & Whitney |

sponsored by

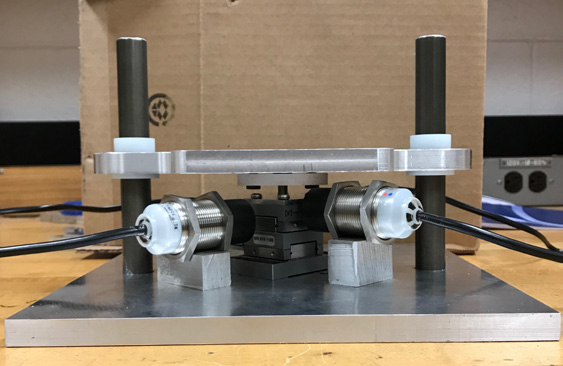

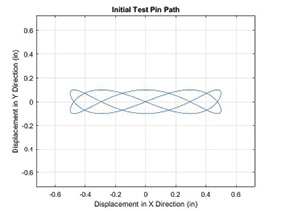

Pratt & Whitney is a global leader in the design and manufacturing of jet engines for commercial and military applications. The company utilizes a large number of resources to conduct wear, or tribology, testing of components in these engines. The goal of this project was to improve testing capabilities to better replicate wear patterns seen in field component hardware. The current test rig in use is capable of testing a single wear mechanism due to relative motion of test specimens being constrained to one axis. A new test rig would introduce a second axis of orthogonal motion to allow for the desired multiple wear mechanism testing. A small-scale prototype for this new test rig was constructed using a commercially available motorized linear XY stage to provide the two axes of relative motion. The normal force needed for wear to occur is provided using a known load above the XY stage surface. Preliminary test runs utilizing the prototype test rig yielded force, displacement, and frequency of motion data for sample multiple wear mechanism tests. This data was utilized to recommend the feasibility of scaling up the prototype design to meet the force, displacement, and frequency of motion requirements needed to fully replicate wear patterns seen in engine field hardware.