Figure 1

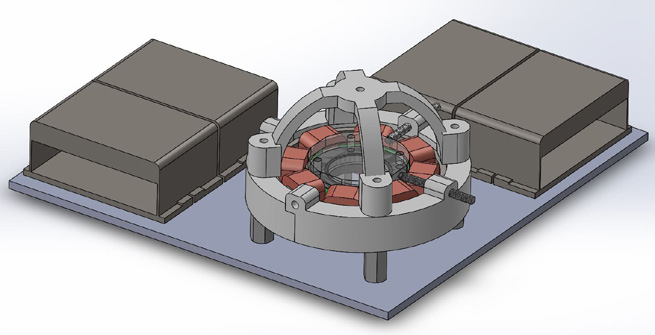

Figure 2

Mechanical Engineering

Team 60

Team Members |

Faculty Advisor |

Nicholas Holden |

Nejat Olgac Sponsor United Technologies Research Center (UTRC) |

sponsored by

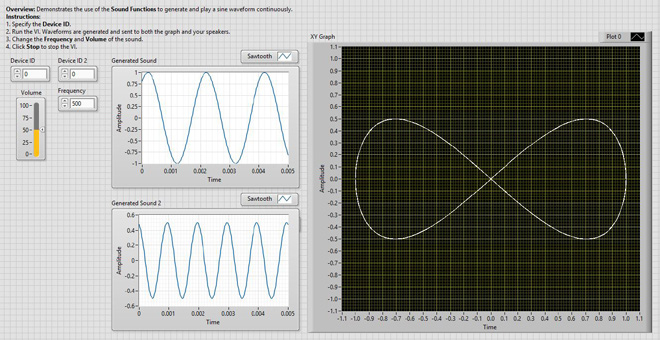

The purpose of this project is to develop an efficient method of simulating different frictional wear patterns between two given surfaces at varying levels of frequency and amplitude. The test fixture we have developed is capable of multi-dimensional wear and has the ability to apply a variable vertical load on the given specimen. The fixture itself also uses an active magnetic bearing, of which we generate a magnetic field to either push or pull a center core whenever needed for a specific wear pattern. The core of the fixture includes a platform of which the specimen will wear against as the magnetic bearing quadrants are energized. To achieve the deliverable of reaching 1000 Hz of low amplitude mechanical vibration, we use a custom LabView file to control the input signal to the amplifiers powering the coils of the magnetic bearing, thus controlling the wear pattern, frequency, amplitude, and other functions for the test fixture. We have also added other data gathering capabilities such as displacement sensors to accurately measure the horizontal displacement of the center core and to verify the accuracy of how the input signal translates to mechanical frequency.