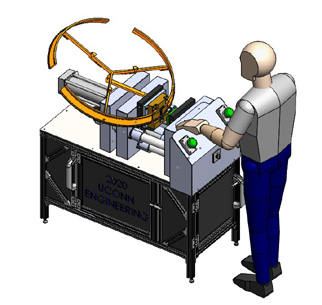

Figure 1

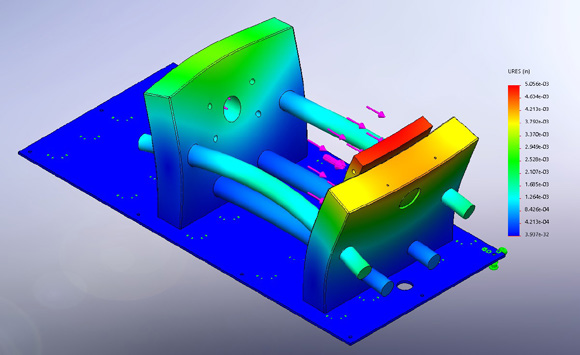

Figure 2

Mechanical Engineering

Team 61

Team Members |

Faculty Advisor |

Seth Beecher |

Vito Moreno Sponsor Whitcraft Group |

sponsored by

Whitcraft is a respected leader in lean manufacturing producing formed, machined and fabricated sheet metal aerospace components and assemblies. They use a hands-on process called Moonshine to aid in rapid prototyping and to develop innovative problem solutions. Our goal was to use the Moonshine process to design a right-sized press machine that shears military engine components. It would replace the existing circa 1950’s press which was big, slow, and cumbersome to operate. The press we designed is portable, easy to use, and fits within Whitcraft’s production flow line, improving efficiency and product output. The Moonshine process consisted of hand-sketching 7 different machine configurations. We chose the best 3 hand-sketches and constructed a cardboard or creform mock-up of each one to understand the basic size and operational limitations of the new design. Once we selected the best of the 3 mock-ups, we created a CAD model and began running simulations. The maximum bending deformation allowed was 0.010”. Our press is 50% of this value, at 0.005” deformation. Our OSHA compliant press machine is designed with a minimum safety factor of 3.5 to ensure proper operation over its lifetime, and features aesthetically pleasing side panels and lighting.