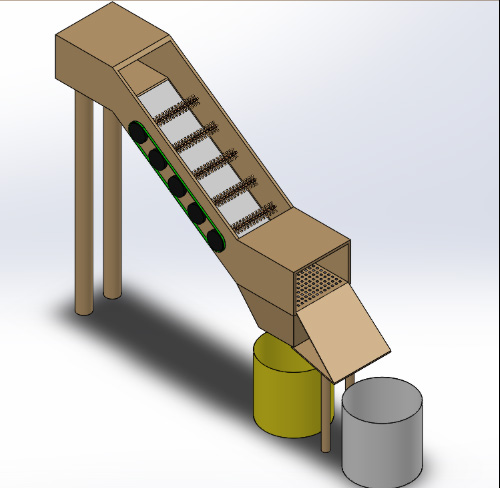

Figure 1

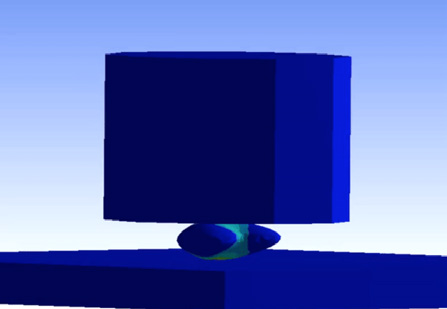

Figure 2

Mechanical Engineering

Team 9

Team Members |

Faculty Advisor |

Jude Andrew Alaba |

Anna Tarakanova Sponsor Cloverleigh Farm |

sponsored by

Cloverleigh Farm is a small farm located in Mansfield, Connecticut, with a focus on community supported agriculture and organic produce. Recently, the farm has begun producing dried beans, a traditionally difficult crop for small farms to manage. After harvest, these plants must be dried, then processed to remove the beans from their pods and the rest of the plant. Previously, this process was entirely manual, resulting in unnecessary labor that could be avoided. The goal of this project was to create a small-scale motorized thresher to expedite the process, resulting in more efficient production and increased profit for the farm. It was important that the device was constructed from inexpensive, locally sourced materials, so the design can be replicated by other small farms in the future. The design concept is derived from a conveyor-belt style mechanism historically used in dry bean threshers. In order to fit the simplicity and ease of maintenance desired by the sponsor, this was adapted into a passive gravity based system where the plants will slide down an angled sheet of UHMW-PE, a durable, low-friction plastic. The plants will then pass through a series of rotating threshers, continuing to an automatic sorting mechanism at the bottom.