Team 10

Team Members |

Faculty Advisor |

William LeMay |

Dr. McCutcheon Sponsor University of Connecticut |

sponsored by

Sponsor Image Not Available

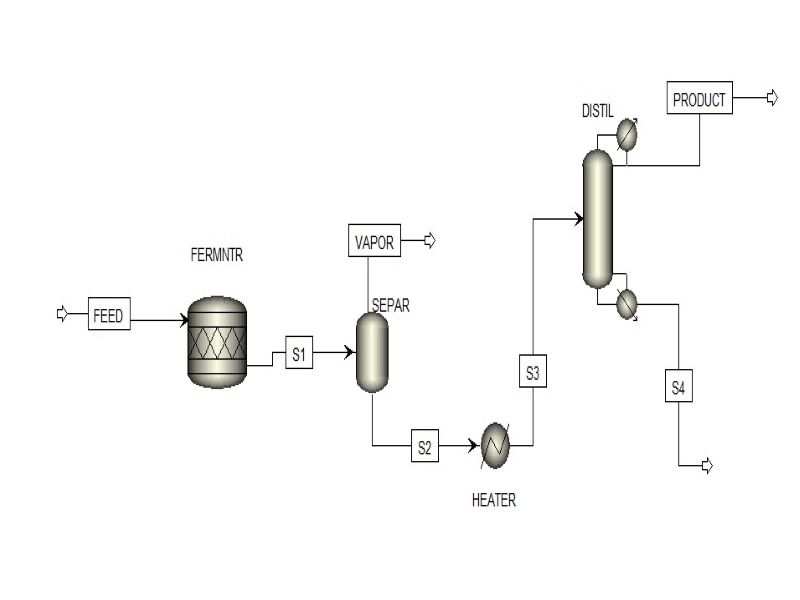

The unexpected and sudden acceleration of the CoVid-19 virus exposed the weakness of the hand sanitizer supply chain industry, especially in the United States. For the first half of 2020, the world was panicking with the onset of the pandemic and there was a noticeable shortage of hand sanitizer supply, which resulted in a significant price gouge. This capstone project contributes to the discussion on supply chain engineering and management, public health, and chemical engineering production by presenting a model for hand sanitizer supply chain production and distribution in response to unexpected market disturbances using the ongoing CoVid-19 pandemic trend in supply chains. The following methods are considered for sourcing alcohol for the production of our hand sanitizer: purchasing bulk ethanol or Isopropyl alcohol, receiving donations for ethanol or Isopropyl alcohol, and manufacturing ethanol or Isopropyl alcohol. Thorough economic analysis, process feasibility and resource availability for the final product will be the metrics used to determine which of the four sourcing options to use. Further product analysis will be done to determine if carbomers or essential oils will be needed to improve the usability of the final product and whether or not this will be financially feasible. Overall, this model relies on a thorough analysis of existing literature, a methodology for the in house setup of an ethanol production process, a plan for repairing the distillation column, an ASPEN model of ethanol and IPA production, a plan for storing and distributing hand sanitizers and an economic analysis that is potentially adaptable for future service learning projects.