Figure 1

Team 11

Team Members |

Faculty Advisor |

Benjamin Flax |

Matthew Stuber, PhD Sponsor Collins Aerospace |

sponsored by

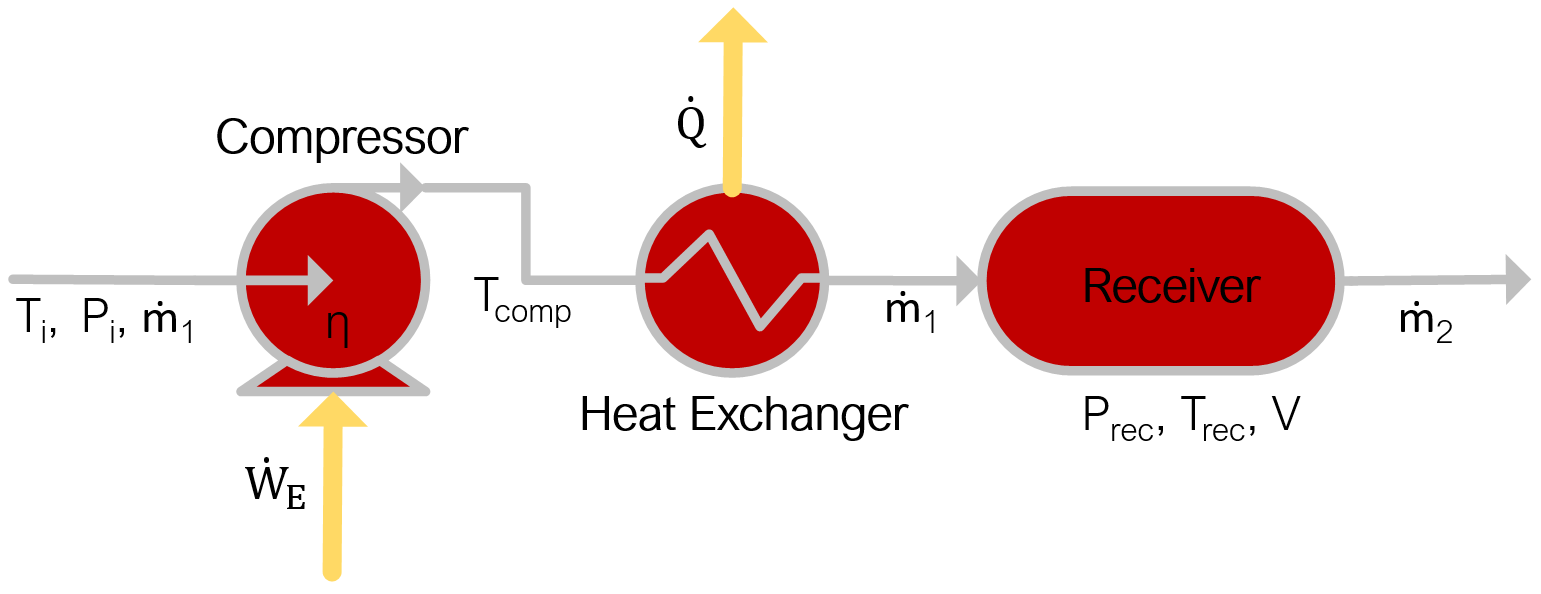

At the Collins Aerospace plant located in Windsor Locks, CT, the facility engineering team has collected a wealth of information on their compressed air system, which is their most expensive utility. This includes power consumption, flowrate, temperature, and pressure data at 5-second intervals in addition to P&IDs and equipment specifications. The goal of our project is to organize and analyze this information, develop a numerical-based model of their air system, compare the results to the data to identify inefficiencies, and make control and design recommendations to improve efficiency and reduce operating cost. We developed our model by creating a process flow diagram of the system and determining the appropriate model equations for each unit operation. Then, we adapted the system for solving in MATLAB. The independent variable in our model is system flowrate, and the dependent variable is system pressure, which is required to calculate other important metrics like compressor power consumption and outlet temperature. Our model is a tool for Collins to analyze various aspects of their compressed air system, including power consumption, inlet conditions, set pressures, and control strategies. It will be adapted as required by the facility engineering team at Collins and has the potential to result in significant performance improvements and energy savings