This video contains proprietary information and cannot be shared publicly at this time.

Figure 1

Figure 2

Team 13

Team Members |

Faculty Advisor |

Lariab Afzaal |

Shinae Jang Sponsor National Guard |

sponsored by

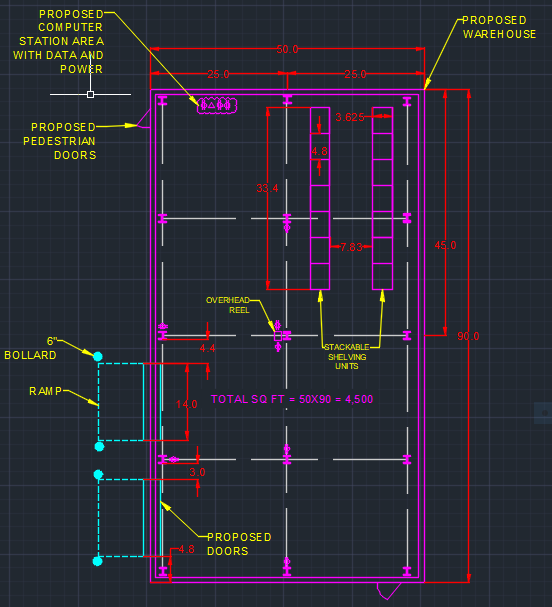

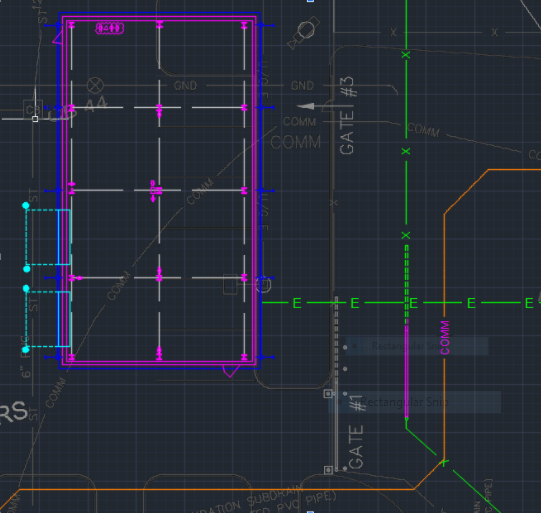

The goal of this project is to build a new warehouse for the 103d Air Control Station to facilitate the Air Force team in Orange, CT. The warehouse will be used to store equipment and to maintained vehicles. Currently, large quantities of readiness equipment and materials are stored outdoors or in temporary locations due to the lack of space. These current methods of storage reduce the functional lifespan of the critical equipment. Therefore a new improved warehouse facility can produce a return on investment by extending the equipment service life and reducing maintenance costs. Our team designed a 50’x90’ warehouse based on design constraints of the Air Force code. The warehouse has a stackable shelving unit for the storage of equipment and 2 roll up doors for the entry/ maintenance of vehicles, with two pedestrian doors. Inside the warehouse are a set of outlets which can be used to power desktops and also power the crane being used in the shelving unit. In addition, the team proposed the relocation of a communications line, which runs right underneath the proposed project site and new fencing placement for security The design includes a new drainage line to dispose of the wastewater to the nearest catch basin, and downspouts to eliminate water runoff on the pavement. A new electrical conduit line will be run from the base transformer. The warehouse is proposed to be built adjacent to the communications tower to mitigate disturbance and to ensure an ample amount of space. A demolition plan shows the area being disturbed, including five parking spaces being affected and the curb in front of the communications tower, along with the wire fencing used alongside the tower. The roof will be sloped and need metal paneling to accommodate the heavy snow loads. A SAP2000 model was used to assess wind, dead, and live loads. A door schedule is included with the plans which shows the dimensions of the doors being used. A cost estimate was also provided for building expenses