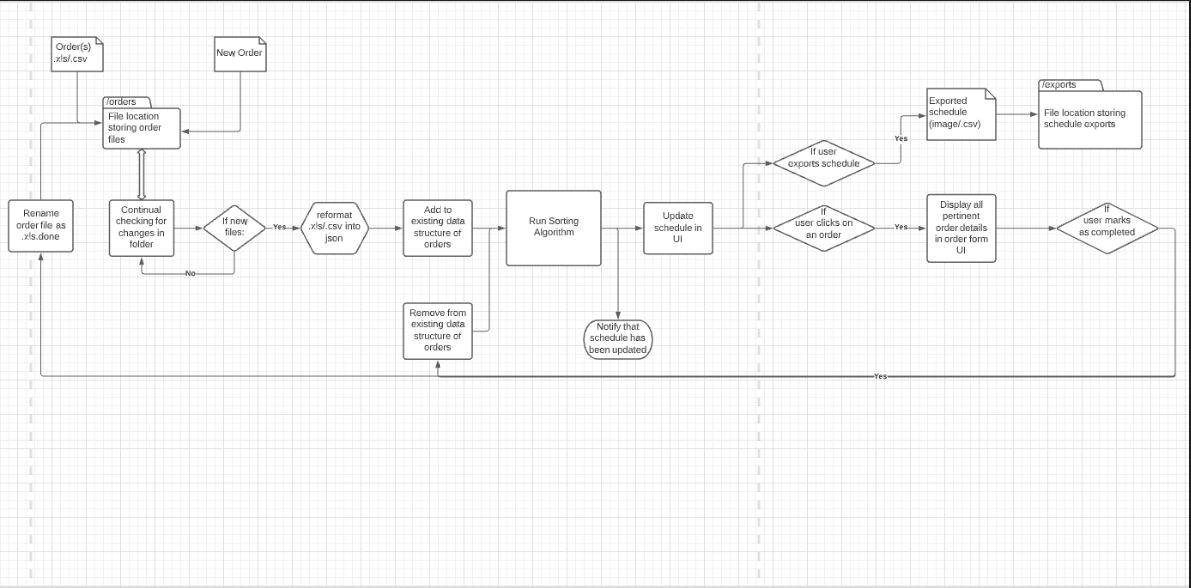

Figure 1

Team 40

Team Members |

Faculty Advisor |

Nic Marchini |

Ion Mandoiu Sponsor Interface Technologies |

sponsored by

In the sewn goods industry, a cutting room is the industrial environment in which materials (usually fabrics) are spread and cut for apparel manufacturing. The processes of spreading and cutting are often complex and challenging to manage. Cutting rooms contain multiple tables on which the material is spread, often in multiple layers (called plys). Often, a manual spreader system is used in conjunction with an automatic cutter. Unfortunately, the automatic cutter systems are usually quite cost prohibitive and as a result a cutting room will often only have one that must be shared. Currently, cutting room managers must manually decide how to schedule the spreading and cutting of different orders in order to utilize these minimal machines and tables. This manual scheduling is suboptimal as it is simply not feasible for a manager to accurately determine the most efficient schedule that satisfies all of the various parameters. To solve this issue, our project team designed and developed an algorithm that, when given a list of cut orders and the needed information about them, will automatically determine what the best scheduling order is based on optimizing a series of factors (order due dates, order priorities, maximum cutter usage, and fastest schedule).