Figure 1

Figure 2

Team 2110

Team Members |

Faculty Advisor |

Austin Benzoni |

Professor Anwar Sponsor National Guard |

sponsored by

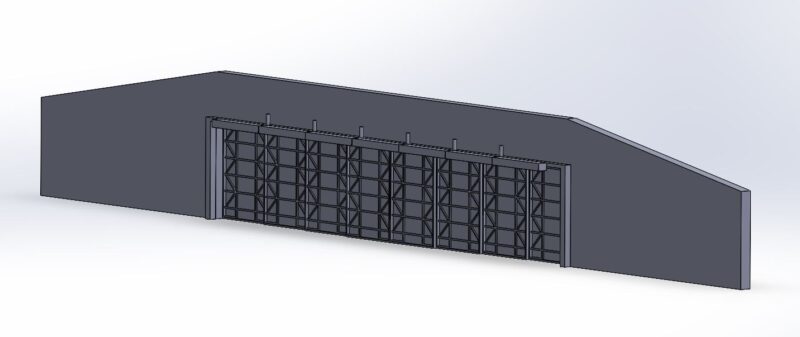

The National Guard located in Groton, CT operates within a large hangar which requires them to open the north and south end hangar doors multiple times per day. Due to its location near the sea, the strong winds combined with the cold winter temperatures can make the working environment uncomfortable for the employees. On top of the discomfort caused, this issue has been putting stress on the heating system utilized to heat the hangar and it has been driving energy costs higher. The reduction of heat loss in the National Guard's hangar is a large scale project. Our electrical and mechanical engineering teams from UCONN are focusing on finding and designing the best possible solution to this problem. The goal of this project is to ultimately increase the comfort of the working environment within the hangar as well as reduce the energy consumption wasted on heating the hangar. The design should not hinder any of the daily tasks completed in the hangar and should be an automated process. Our team is pursuing an air wall system composed of various air blowers, a suspension system to hold the machinery, and switches to automate the blowers. This design is the least obtrusive on the activities which take place in the hangar. Due to the large scale of this project our team is building and simulating the final design of this project and presenting the completed system design to the National Guard.