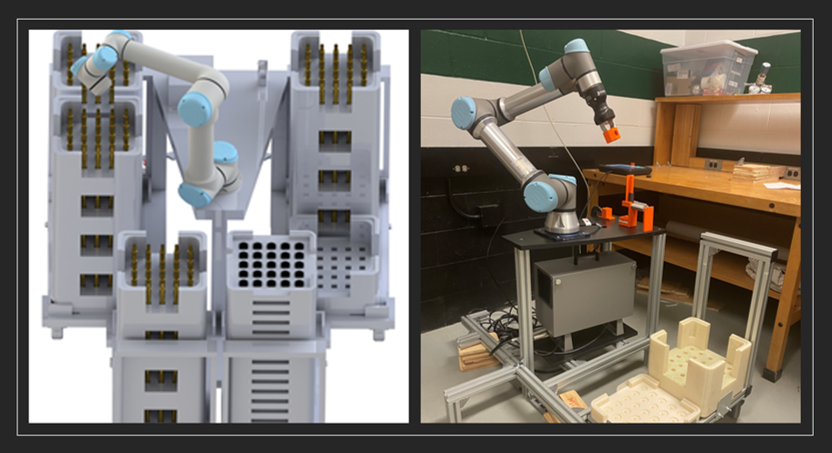

Figure 1

Team 1

Team Members |

Faculty Advisor |

Joshua Macchi |

Craig Calvert, Frank J. Cunha Sponsor Belimo Americas |

sponsored by

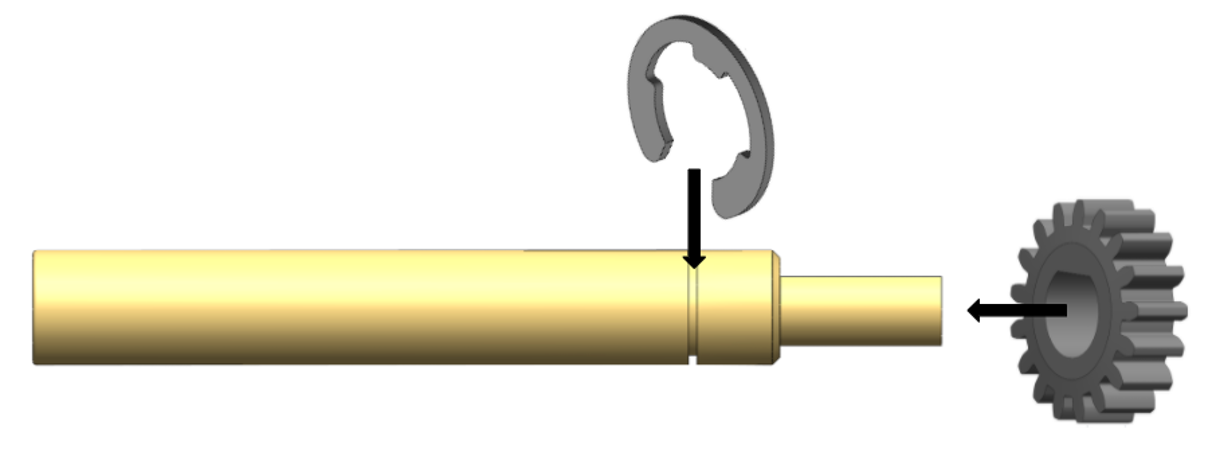

Belimo is the global market leader in the development and production of valves, actuators, and sensors for controlling heating, ventilation, and air conditioning systems. To save money on assembly and increase the amount of product the company can produce, manufacturing automation is being explored for smaller assemblies at Belimo’s North American headquarters located in Danbury, Connecticut. The goal of the project is to implement an automated assembly system for a gear and shaft sub-assembly utilizing a collaborative robot. The Universal Co-Bot UR5e was chosen to handle this gear and shaft assembly which would limit human involvement. Our team has built a physical, fully integrated RPA solution that can have a positive impact on Belimo’s bottom line upon delivery. While granting the agility, efficiency, and performance manufacturers are looking for today, our solution achieves a 46.52% ROI compared to a commercial competitor. With the assembly process being automated, Belimo will experience shorter lead times, decreased operating expenses, and increased available human capital. Working jointly with Mechanical Engineering team 09, our team was able to develop this automated application through the design of mechanical components needed for the unique assembly and through the efficient programming of the cobot that allowed for the assembly iteration over palletized components. Belimo will be provided with comprehensive standard work for the programming of the cobot which will allow them to expand automated capabilities in the future at the Danbury site. This project gives Belimo an even greater advantage to maintain their position as a global market leader in the HVAC industry.