This video contains proprietary information and cannot be shared publicly at this time.

Team 8

Team Members |

Faculty Advisor |

Karl Douglass Mueller |

Dr. Rainer Hebert Sponsor Lockheed Martin |

sponsored by

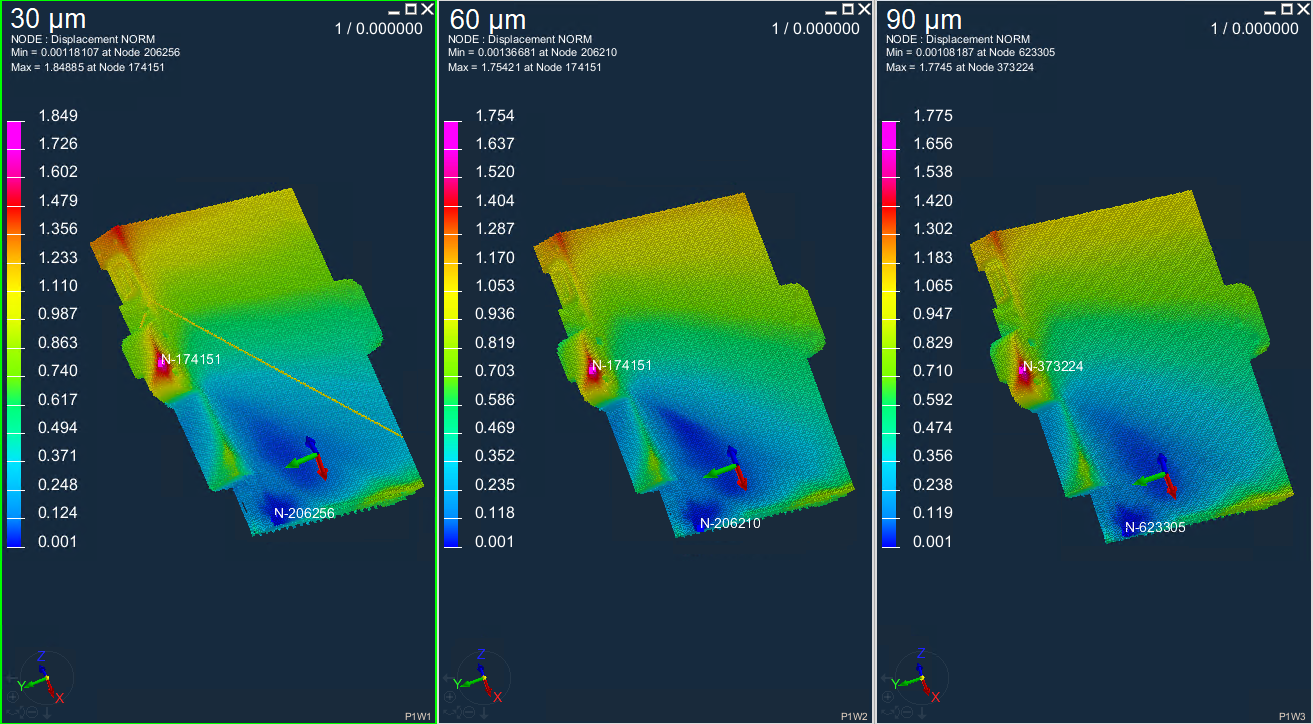

The project involves the simulation and analysis of how various layer heights affects distortions induced in a part produced with a metal-based laser powder bed fusion (LPBF) additive manufacturing process. LPBF involves the deposition of a layer of powdered metal, applied in a controlled height, onto a base plate which is melted by laser at controlled power and scanning speed. While there are other parameters, such as part orientation and hatch spacing, this project is mainly concerned with the effects that layer height, laser power, and laser speed have on the deviations from the designed geometry. This project utilizes ESI's Additive Manufacturing software suite to calculate thermal gradients and distortions at key points during the process. The specific objective of this project is how layer heights between 30-90 microns will affect the final part geometry.