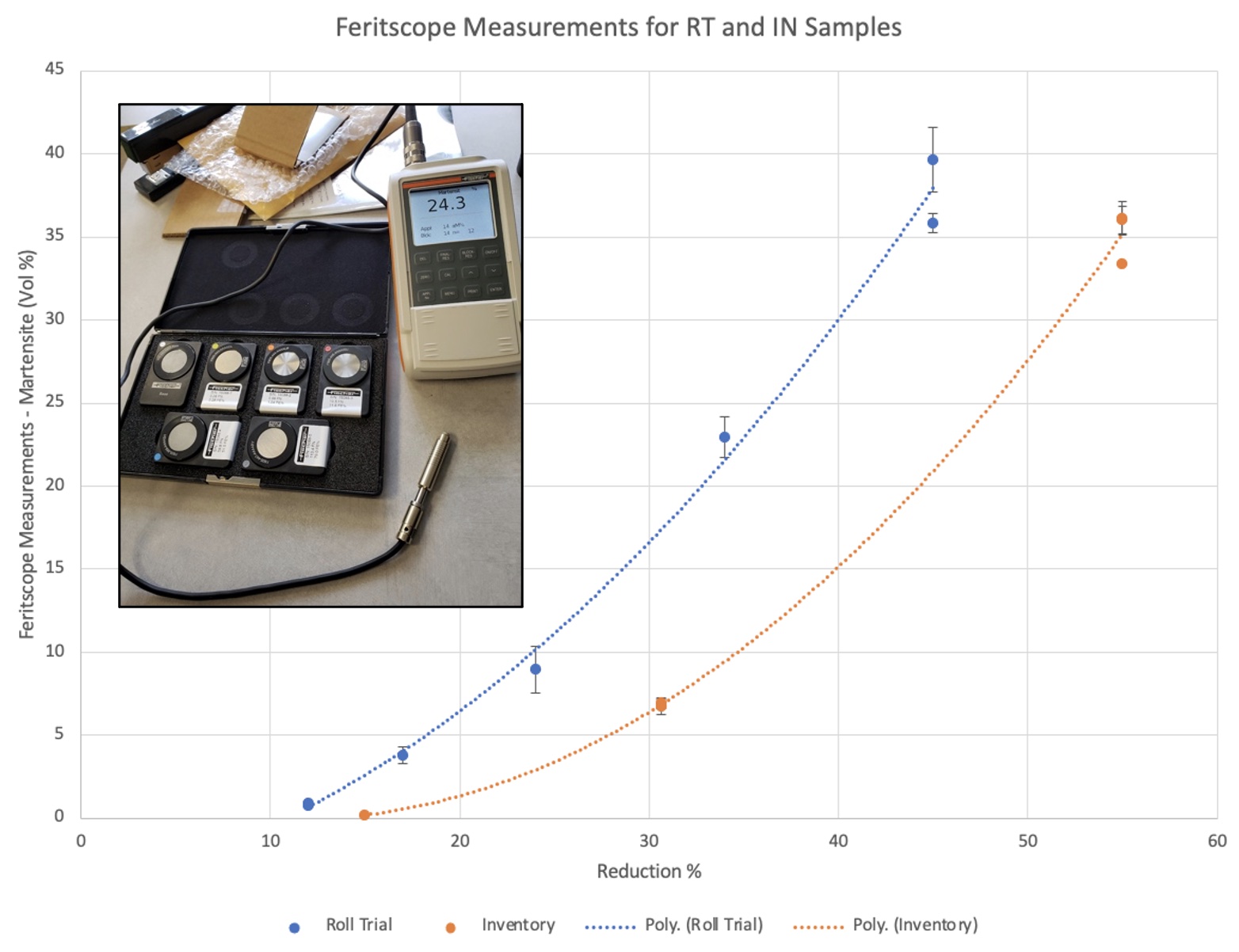

Figure 1

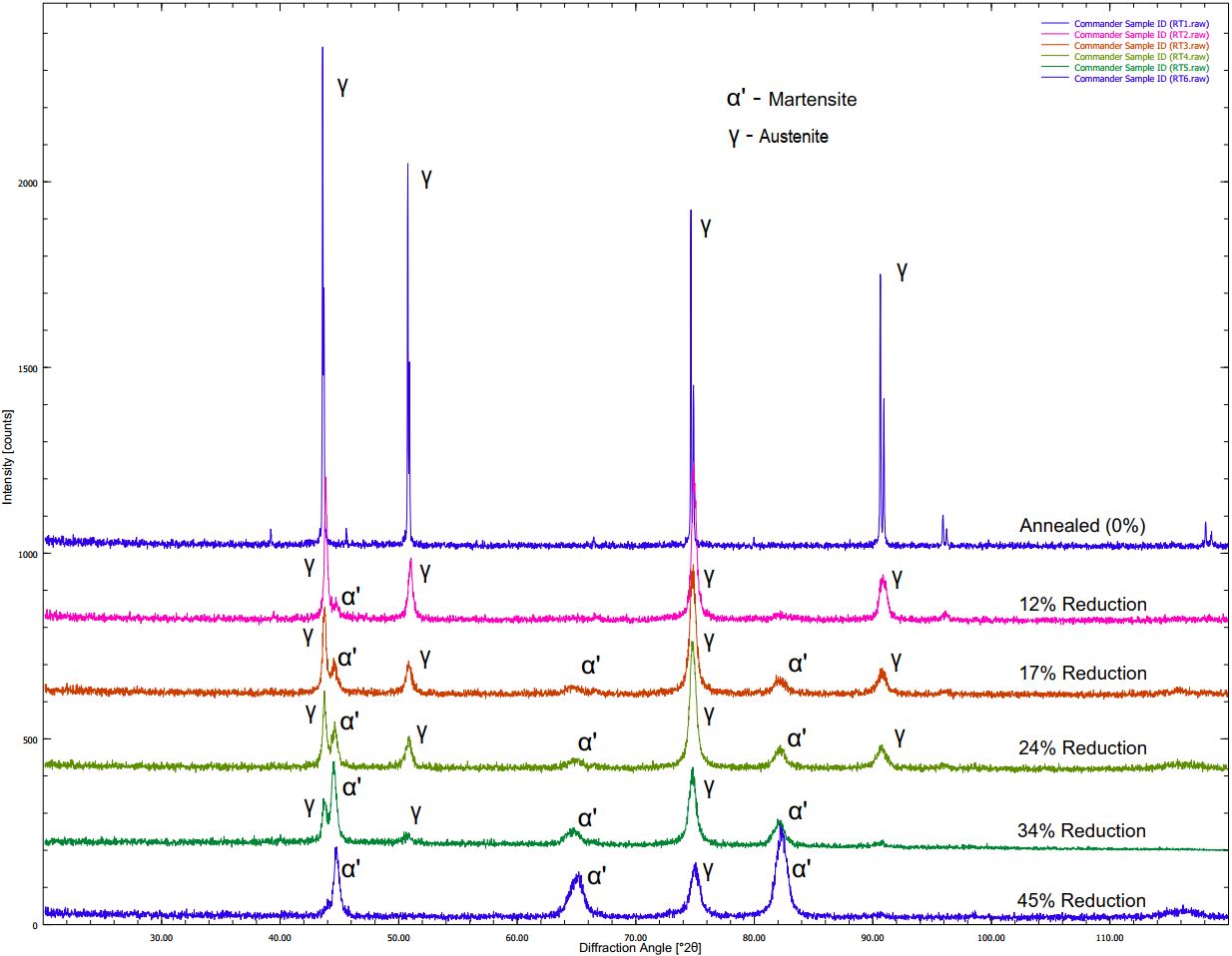

Figure 2

Team 9

Team Members |

Faculty Advisor |

Alex Distelman |

Dr. Yuanyuan Zhu Sponsor Ulbrich Stainless Steels & Specialty Metals |

sponsored by

The focus of this project is to enable our sponsor, Ulbrich Stainless Steel and Special Metals, to measure the amount of martensite in their 301 stainless steel sheet products. The ability to monitor microstructural developments during processing ensures that the final product will exhibit the desired mechanical properties. Martensite forms from the austenite phase during cold rolling deformation. This diffusionless phase transformation from FCC γ-austenite to BCC α’-martensite corresponds directly with increases in the 301SS’s strength and hardness. These microstructural changes to the austenitic stainless steel’s structure enable martensite to be identified through advanced microscopy techniques. These techniques, such as SEM, XRD, and EBSD, can identify the crystal structure and morphology changes of the 301SS, and enable the quantification of the present phases of the steel. However, the previously mentioned techniques are expensive, require intensive training, and are time-consuming to run. Therefore, determining an inexpensive, easy, and fast method to determine the volume fraction of martensite in 301SS would be desirable for maintaining the production quality of rerollers.