Figure 1

Figure 2

Team 25

Team Members |

Faculty Advisor |

Nathan Berardi |

Reza Sheikhi Sponsor Holo Krome |

sponsored by

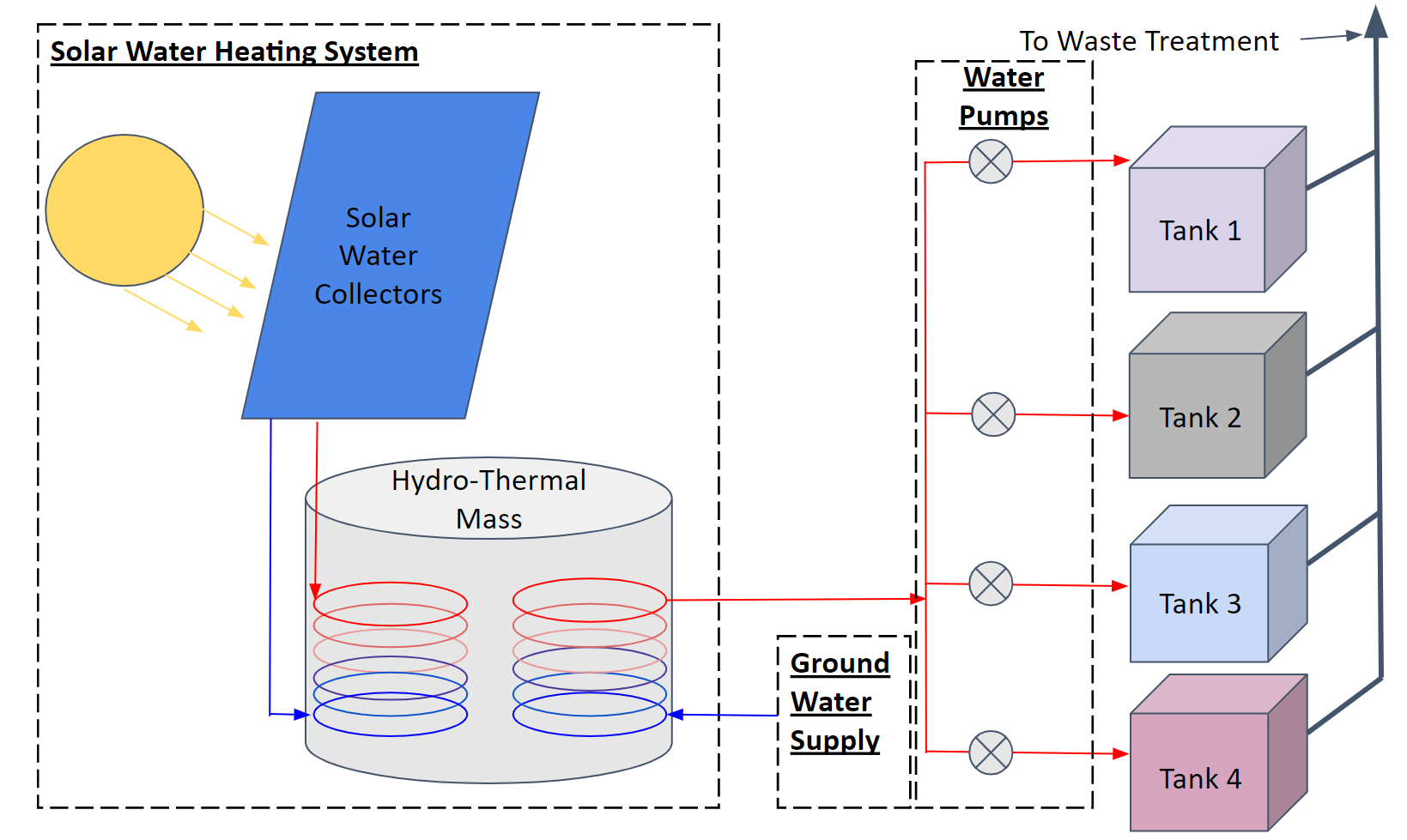

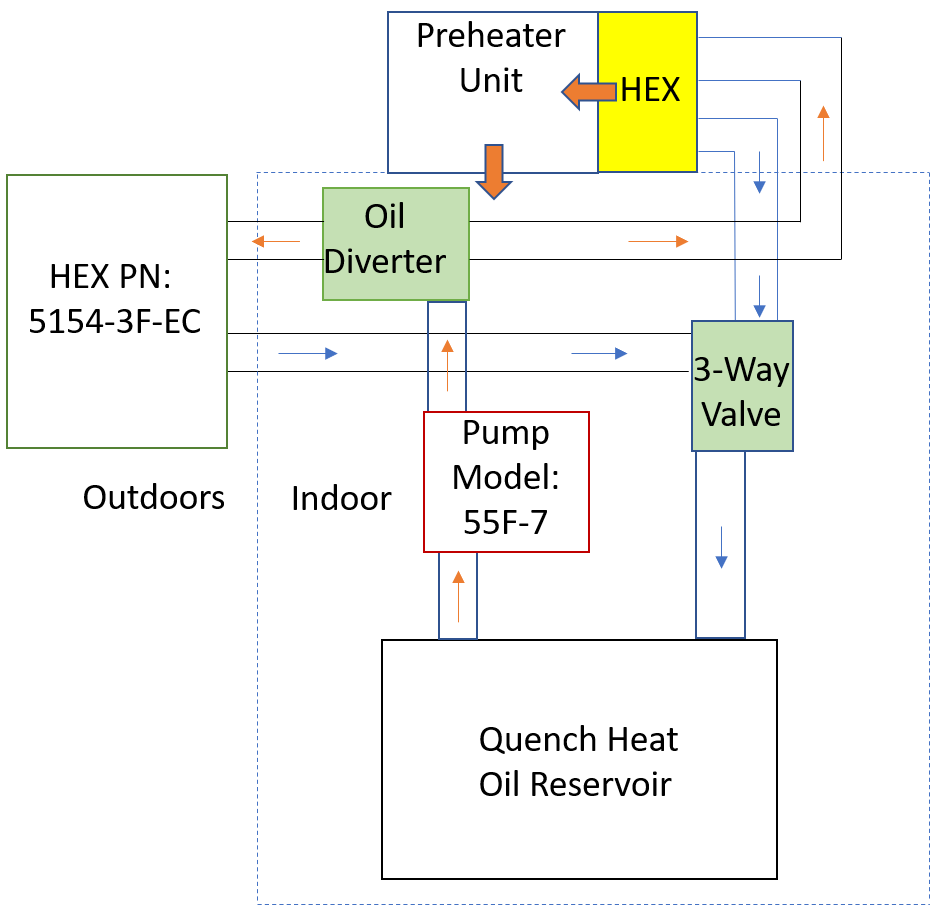

Holo-Krome, located in Wallingford, CT, is a fastener manufacturer which prides itself in product quality and sustainability. They have been taking great strides to lower their carbon footprint, and find ways in which they may maximize their plant efficiency and lower overall fossil fuel and energy consumption. Our task is to research and develop plans for implementation of candidate heat generation systems to reduce or eliminate consumption of natural gas and electricity usage in applicable industrial processes at their plant. The first design involves utilizing the quench oil of a heat treat furnace redirected into the heat exchanger that would provide preheated air to a roof mounted natural gas heater. This preheated air will reduce natural gas usage in the pre-heater leading to lower annual heating costs. The second option involves utilizing solar heating to supplement electric heating for the fastener finishing process. Solar thermal collectors utilize a water tank as a thermal mass preheating fresh water supplied to finishing tanks maintained at 150°F to 180°F. Increasing temperature of fresh inlet water reduces electricity required by existing low wattage tube heaters. Each design has been modeled to determine system capability and return on investment.