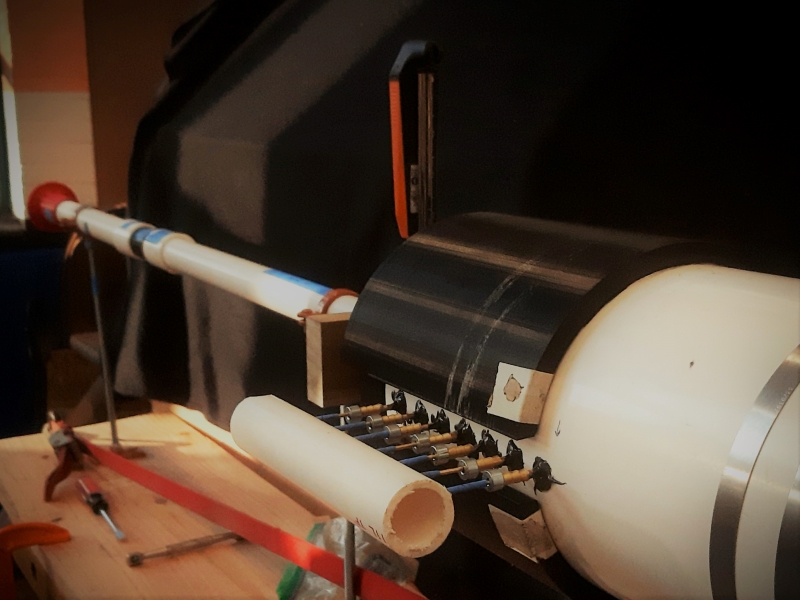

Figure 1

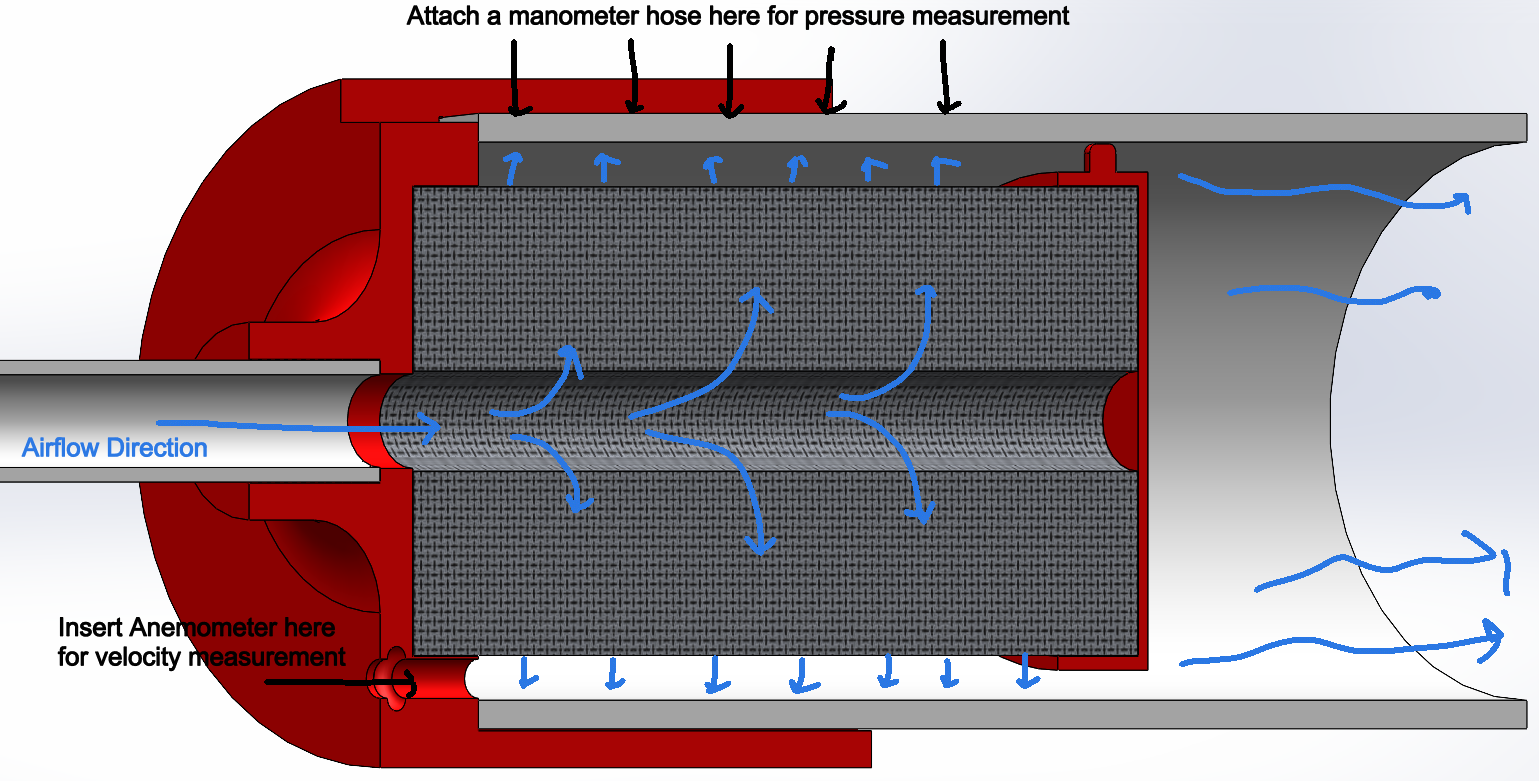

Figure 2

Team 37

Team Members |

Faculty Advisor |

Austin Gray |

Alexei Poludnenko Sponsor Precision Combustion Inc. |

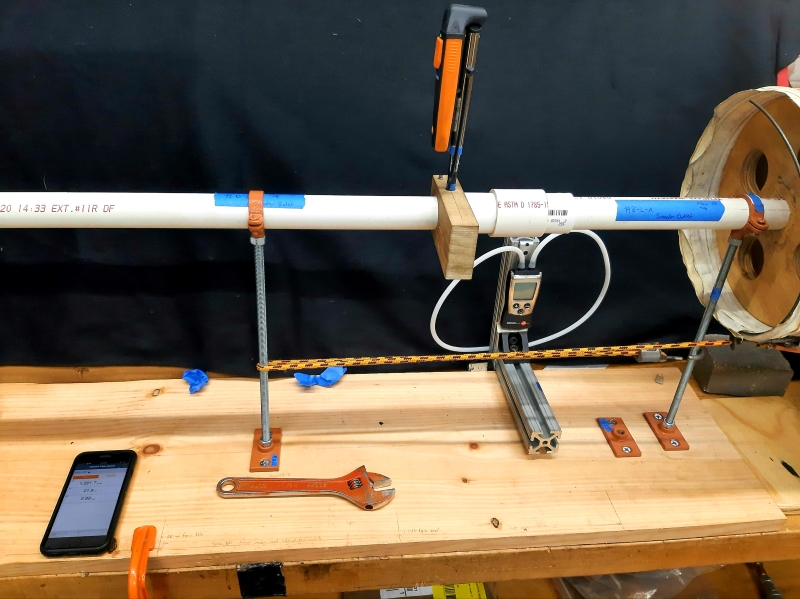

sponsored by

Precision Combustion Inc.’s (PCI) Microlith@ catalytic reactor design is compact, lightweight and highly efficient. It offers major performance and cost advantages when compared to conventional state of the art catalytic reactors. These catalytic reactors consist of multiple layers of expanded metal mesh. They have two primary configurations of this mesh: planar flow through a linear stack of circular screens; and radial flow through a roll of mesh plugged at the downstream end. PCI has obtained some simulation and experimental data on their planar flow configuration, but they have no performance data on the radial flow configuration. To provide this critical data, we have developed an experimental test rig and an ANSYS flow simulation. The relevant performance metrics are pressure drop and outlet velocity across the mesh assembly for each configuration. The experimental rig was designed to facilitate precise and efficient testing of the two mesh configurations. Sections containing each mesh configuration as well as rig sections housing the flow instrumentation are able to be exchanged easily to resume testing. Two sensors were used for testing in the experimental rig: a hot-wire anemometer for velocity measurements, and a manometer for pressure differential measurements. The results from testing confirmed PCIs results for the planar flow configuration. As predicted by our theoretical model, pressure drop across the mesh stack increased parabolically with increasing inlet velocities. Due to damage to the mesh roll, we were unable to obtain conclusive data for the radial flow configuration. Finally, we were able to provide recommendations for PCI’s future product assembly and experimentation procedures for both configurations.