This video contains proprietary information and cannot be shared publicly at this time.

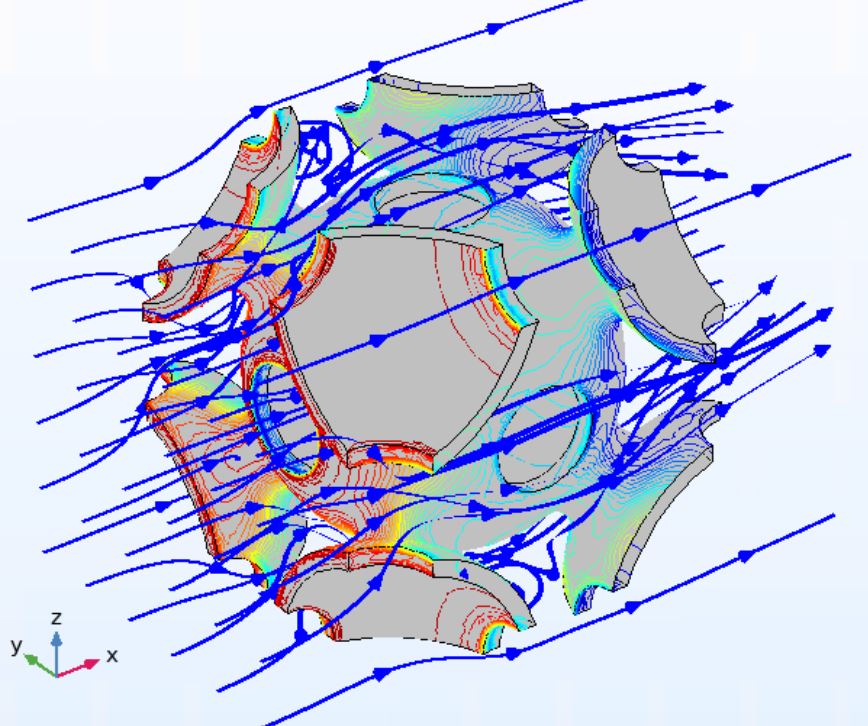

Figure 1

Team 54

Team Members |

Faculty Advisor |

Eva Gurra |

Wilson K.S. Chiu Sponsor UCONN, Dr Chiu |

sponsored by

Conventional open-cell foams are porous, light-weight materials promising for heat transfer augmentation. They play an important role in the aerospace industry, thermal insulation, heat exchangers, and even in heat sinks for electronic power dissipation. Our advisor and collaborators have performed extensive simulations and research on various types of foam models including symmetrical models like Kelvin, Wearie-Phelan and tomography reconstructed foams and have developed correlations for these studies. In this project, we performed similar thermal-fluid analyses of a new custom architectured open-cell foam how foam properties such as porosity, cell size, and other geometrical parameters affect heat transfer. Using COMSOL Multiphysics, we performed conduction and convection heat transfer simulations and varied several geometrical parameters in the foam to determine the configuration that would optimize heat transfer. We quantified heat transfer optimization with the calculation of the effective thermal conductivity (ETC), Reynolds number, Nusselt number and pressure drop. Finally, we developed the correlations for the effective thermal conductivity and Nusselt number as a function of several geometrical parameters in the foam including porosity, binder angle, and thickness. We have shown that architectured foams are promising for heat transfer and have developed new correlations on these geometries. We showed that we can modify the geometry to reach as low as a 15% deviation of the parallel model (an upper bound on ETC). We have also calculated a higher Nusselt number compared to the Kelvin foam model at equal porosity.