Figure 1

Figure 2

Team 20

Team Members |

Faculty Advisor |

Christopher Morse |

Lei Wang Sponsor ACMT, Inc. |

sponsored by

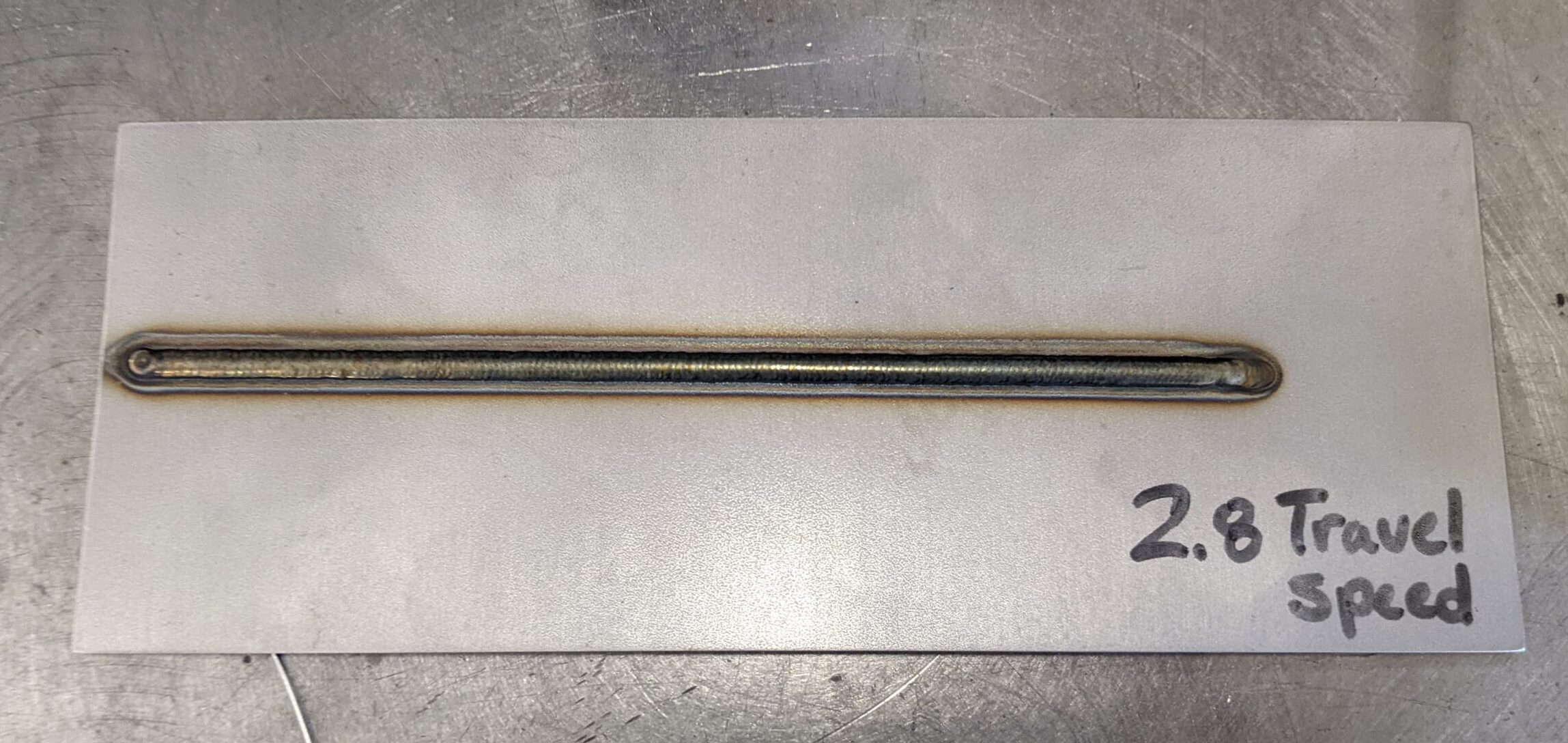

Feasibility of Robotic Welding of Complex Aluminum Panels

Aerospace manufacturing continuously holds rigorous standards in both production quality and project deadlines. The use of robotic arms is becoming more common in the industry as a way of speeding up repetitive tasks while still maintaining high standards. This project demonstrates the feasibility and capabilities of an ABB robot equipped with a TIG (tungsten inert gas) welding apparatus to join complex aluminum panels. The successful implementation of this machine into a manufacturing setting would decrease production time and costs while maintaining the high standards necessary to operate within the aerospace industry. One of the many challenges to overcome in this project included pinpointing the precise movements and timing for the heating and cooling of each unique part. Once those unknowns are solved and proper fixturing is made for each piece to be joined, an ABB robot equipped with a TIG welding apparatus can become a pivotal element of any manufacturing process.

Our team collaborated with Mechanical Engineering 1 on this project.