This video contains proprietary information and cannot be shared publicly at this time.

Figure 1

Figure 2

Team 08

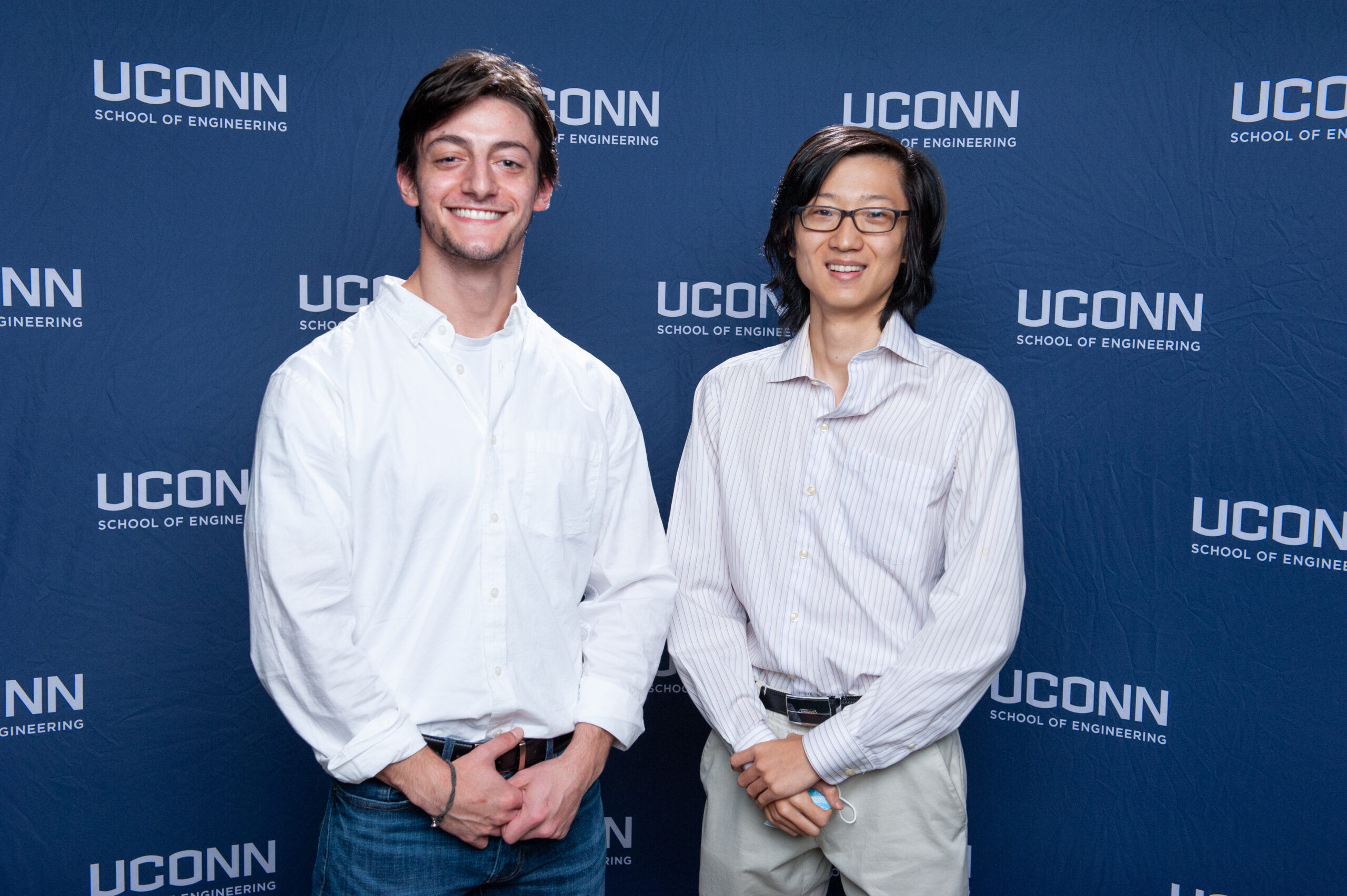

Team Members |

Faculty Advisor |

Xiaoyang Ma |

Thanh Nguyen Sponsor ASML |

sponsored by

Mechatronic Actuated Optics

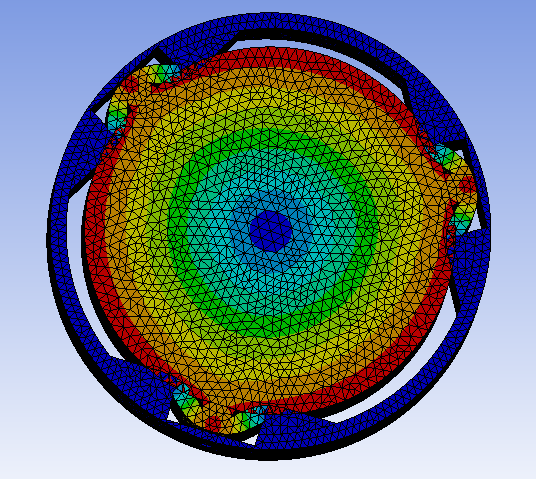

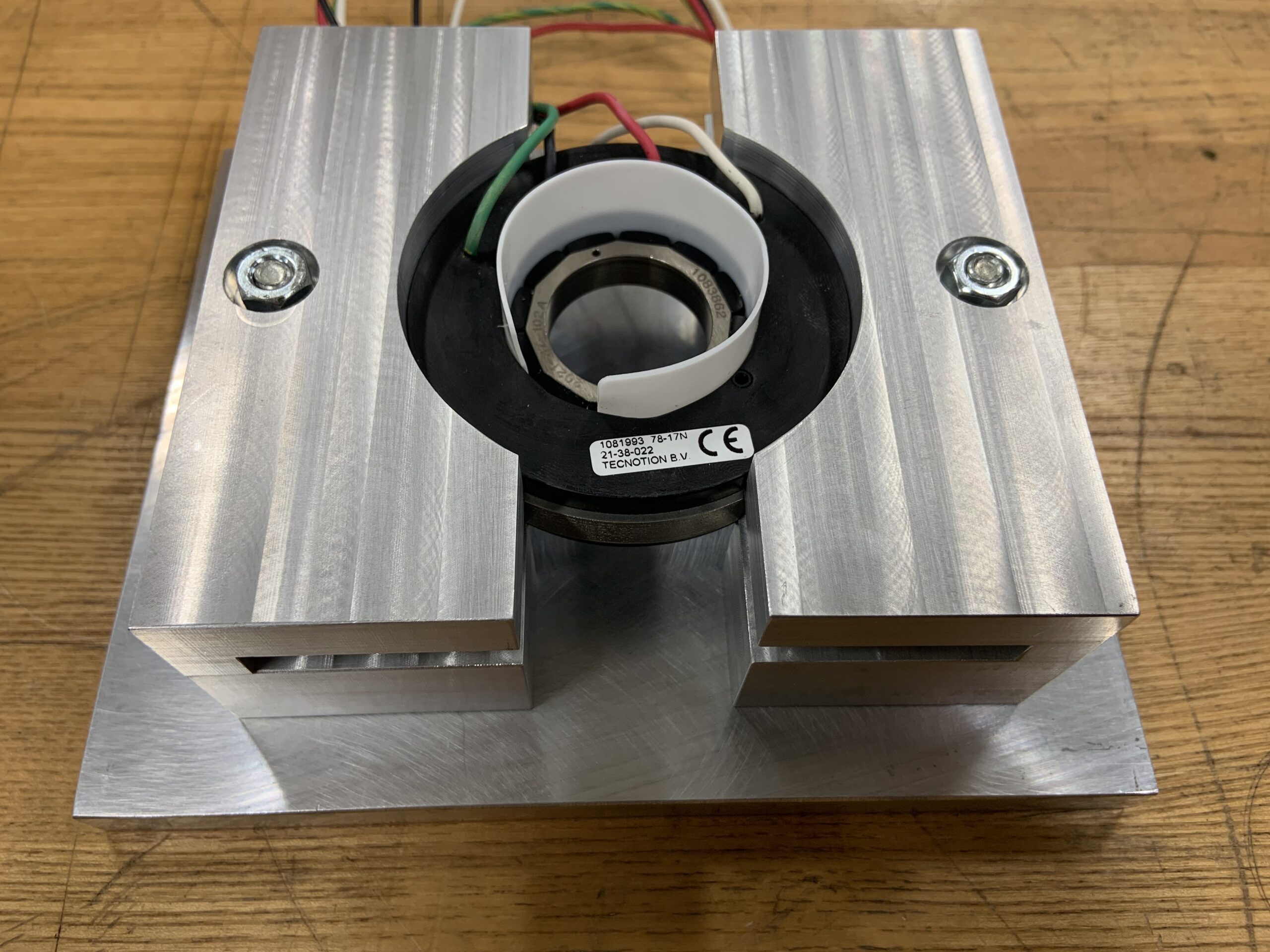

ASML specializes in semiconductor technology and is one of the world’s largest suppliers of lithography systems. With headquarters located in the Netherlands, the company has offices all around the world; utilizing advanced technologies to constantly improve their research and development. ASML uses specialized optic lenses for various applications in its lithography processes. These lenses are rotated by motors to accurately control light. The nature of the lithography process demands motors to perform with high precision, quick response time, and low thermal output among other strict requirements. Piezoelectric motors are well suited for these specifications; however, not cost-effective. Over the course of the past two semesters, the UCONN School of Engineering senior design team, ME08, was tasked with researching more cost-effective alternative technologies with traditional electric motor architecture. The goal was to find a conventional option that is capable of achieving similar performance characteristics to their expensive piezoelectric counterparts. Both off-the-shelf and custom-built options were reviewed. After thorough consideration, the team down-selected a direct-drive BLDC motor for proof-of-concept testing. A test fixture to house the motor, as well as flexure design for optomechanical purposes were designed. The flexure secures a 3D-printed disk to replicate a lens that ASML would use in its real-life applications. Modal, positioning accuracy, and thermal analysis were performed; A proof of concept system was designed, manufactured and tested, although a significant amount of work remains to industrialized this system to meet all performance requirements, the results of this project will nevertheless aid ASML in improving its lithography systems.