Figure 1

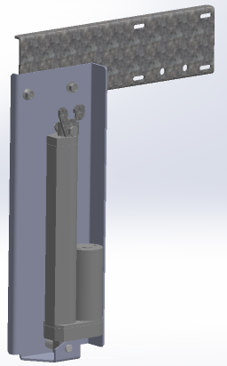

Figure 2

Team 23

Team Members |

Faculty Advisor |

Cal Pitruzzello |

David Giblin Sponsor Other |

sponsored by

Fastcorp Vending Machine Design for Cost Reduction and Functional Improvement

The objective of this project is to reduce the cost of the freezer door lift system for Chapco and Fastcorp’s Dream-It-Vend-It (DIVI) vending machine by reducing the assembly time required. The team is providing Chapco and Fastcorp with a new assembly to lift the freezer to replace the existing system. The freezer is inside the vending machine where the products are stored in bins. The freezer door has to automatically open to let a suctioning system pick up the product and place it in the bin for the customer to take. The existing system that automatically opens and closes the door on the freezer has a great number of parts, fasteners, and often requires troubleshooting to get it working before being sold. The team designed a new system that takes advantage of a commercialized linear actuator to reduce the number of fastening operations from 16 to 3, the number of in house made parts from 5 to 3, and to eliminate all outsourced machined parts. This reduces the assembly time and simplifies the process to build the system while not increasing the cost of parts. The team utilized Matlab to calculate the dynamics of the mechanism to optimize the force exerted onto the door and the time required to lift the door. After selecting an actuator that met the requirements given from the simulation, and was in budget, the team prototyped with the actuator to get a working system. Brackets to mount the actuator were designed in Solidworks and validated structurally using ANSYS Static Structural. The team designed and programmed an electronic control system prototyped with Arduino to implement into the vending machines control board. The code will then be programmed into the vending machine’s control board. The DIVI XL, a larger version of the DIVI, uses a custom designed control board so the new system will be first implemented into the DIVI XL. The original DIVI will use the new system once it’s main control board updates to the DIVI XL's control board.

Our team collaborated with Electrical and Computer Engineering 21,Management & Engineering for Manufacturing 5 on this project.