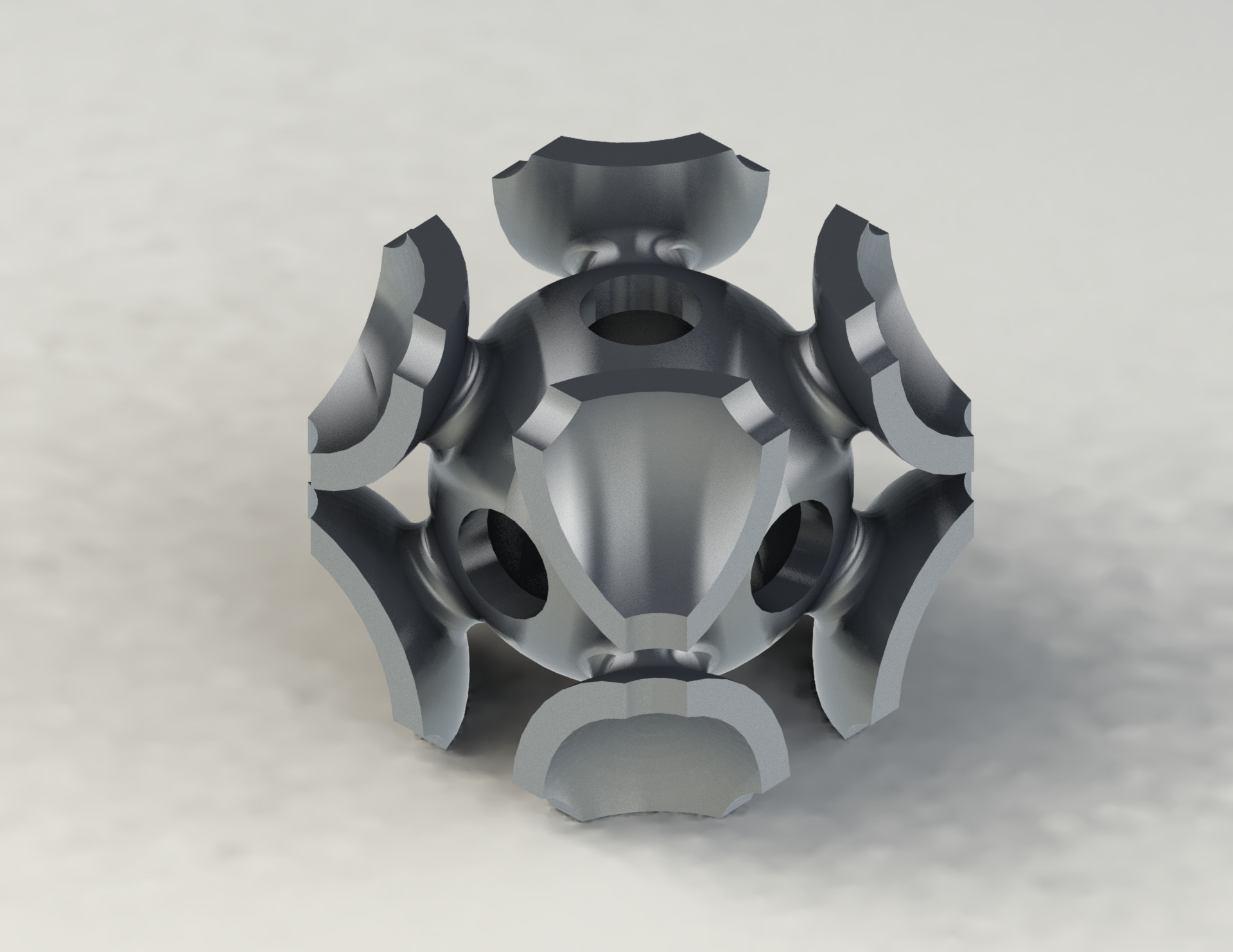

Figure 1

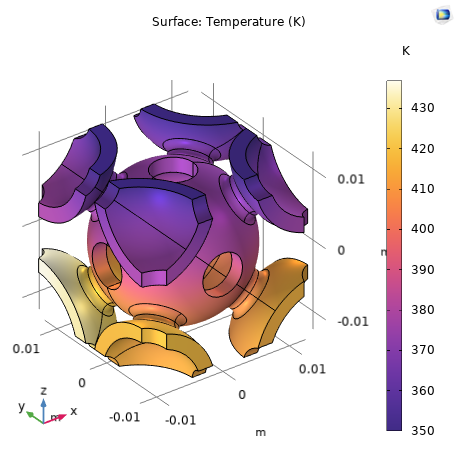

Figure 2

Team 74

Team Members |

Faculty Advisor |

Maxwell Bartlett |

Dr Wilson Chiu Sponsor UCONN, Dr Chiu |

sponsored by

Intelligent Design of Architected Open-Cell Foams

Novel advancements in manufacturing technology allows for greater precision in printing 3D metal structures. This makes the production of metal architected open cell foams possible. Architected open cell foams are comprised of repeating connecting unit cells, are light weight and may have high heat transfer rates for how light they are. These properties are ideal for use in heat exchangers. The optimal geometric configuration of these open cell foams to maximize effective thermal conductivity is currently unknown. The purpose of this project is to use machine learning to discover the optimal foam geometry to maximize effective thermal conductivity. This will be achieved by implementing a Genetic Algorithm within MATLAB. The Genetic Algorithm will start with an initial population of foam geometry configurations. It will then use COMSOL simulations to evaluate the performance of each specific geometric configuration. The performance of each configuration will then be transferred into MATLAB, which will generate a new collection of foam geometries based off the most effective previous configurations. The new geometries will then be reevaluated in COMSOL, and the process will continue until the most optimal foam configuration is discovered This work was performed in collaboration with Gerardo Maria Mauro at the Università degli Studi del Sannio, and Marcello Iasiello, Nicola Bianco and Vincenzo Naso at the Università degli Studi di Napoli Federico II, with support from an Italian Government MIUR Grant No. PRIN-2017F7KZWS.