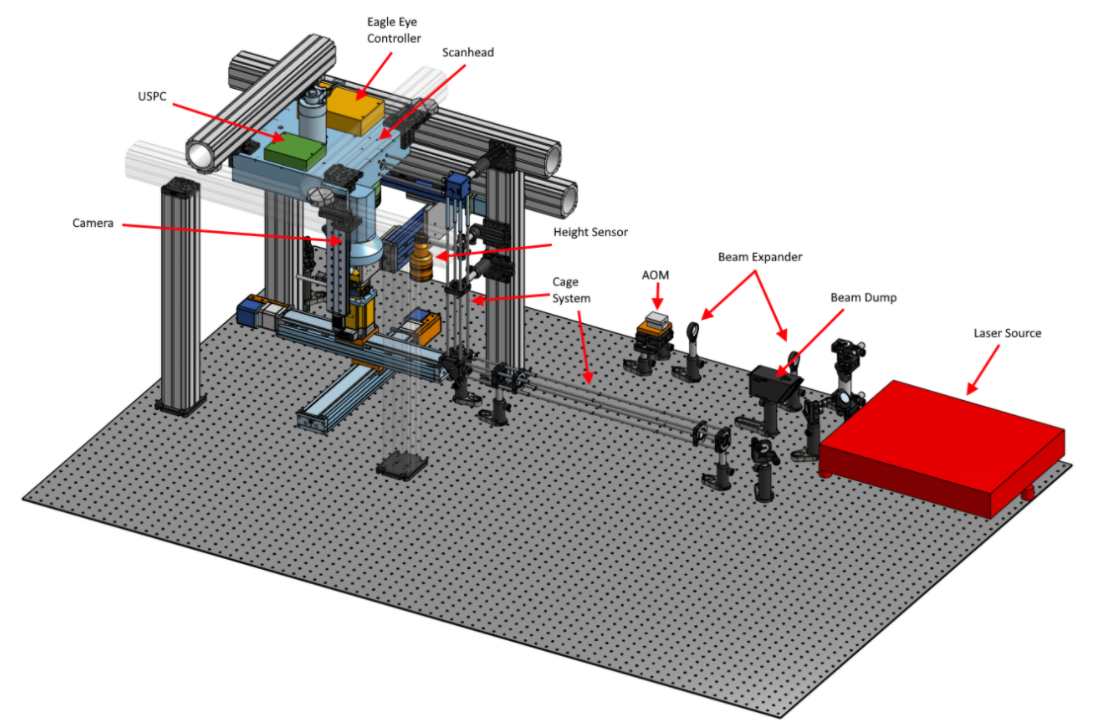

Figure 1

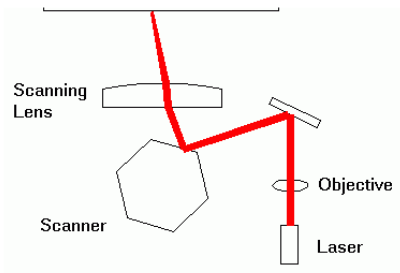

Figure 2

Team 75

Team Members |

Faculty Advisor |

Alexander Blagojevic |

Dr. Sina Shahbazmohamadi Sponsor Other |

sponsored by

Design and Build of a Precision Polygon Scanning Femtosecond Laser Set-Up

For many micromachining applications that require especially high levels of precision, high-powered ultra-short pulse (USP) lasers have been shown to outperform their continuous or longer pulsed counterparts, in terms of machined surface quality. USPs operate on the principle of high intensity, short pulses of light, in the order of a few dozen femtoseconds to 10 picoseconds. These short pulses allow for more precise machining, by minimizing the amount of heat transferred to the area surrounding the target. Currently, femtosecond lasers are limited in positioning speed due to the acceleration of the galvanometer mirrors that align the laser bottlenecking certain beam parameters. For example, to achieve a 50 percent pulse overlap at 2 MHz the beam would need to move at a velocity of 15 meters per second, while the limit of a typical galvanometer configuration is 11 meters per second. The objective of the project is to design, build, and calibrate a femtosecond laser system that utilizes a polygon scanhead and other optical components to overcome these speed limitations, achieving precise scanning control and greater versatility of beam settings. A polygon scanner replaces one of the galvo mirrors with a rotating polygon whose sides are coated in reflective material. The polygon scanner’s maximum angular velocity is 10,000 RPM, which yields a scan speed of at least 180 meters per second. This faster scan speed allows for experimental designs that aren’t otherwise possible and achieves a higher quality scan. Existing polygon scan head technology is typically used with larger spot sizes for applications such as laser printing, but has seen limited use in micromachining. Our design is unique, as it utilizes a beam with a small spot size for more precise applications in micromachining, such as laser polishing and thin film removal. This system needs to be high functioning, complete, and repeatable for future marketing and professional use.