Figure 1

Figure 2

Team 4

Team Members |

Faculty Advisor |

Cat Odendahl |

George Bollas Sponsor Nel Hydrogen |

sponsored by

Computational Fluid Dynamics Analysis and Symbolic Regression of a Water-Oxygen Separator in the Hydrogen Production Process

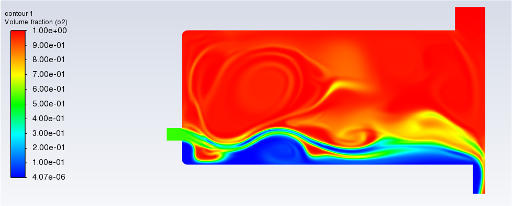

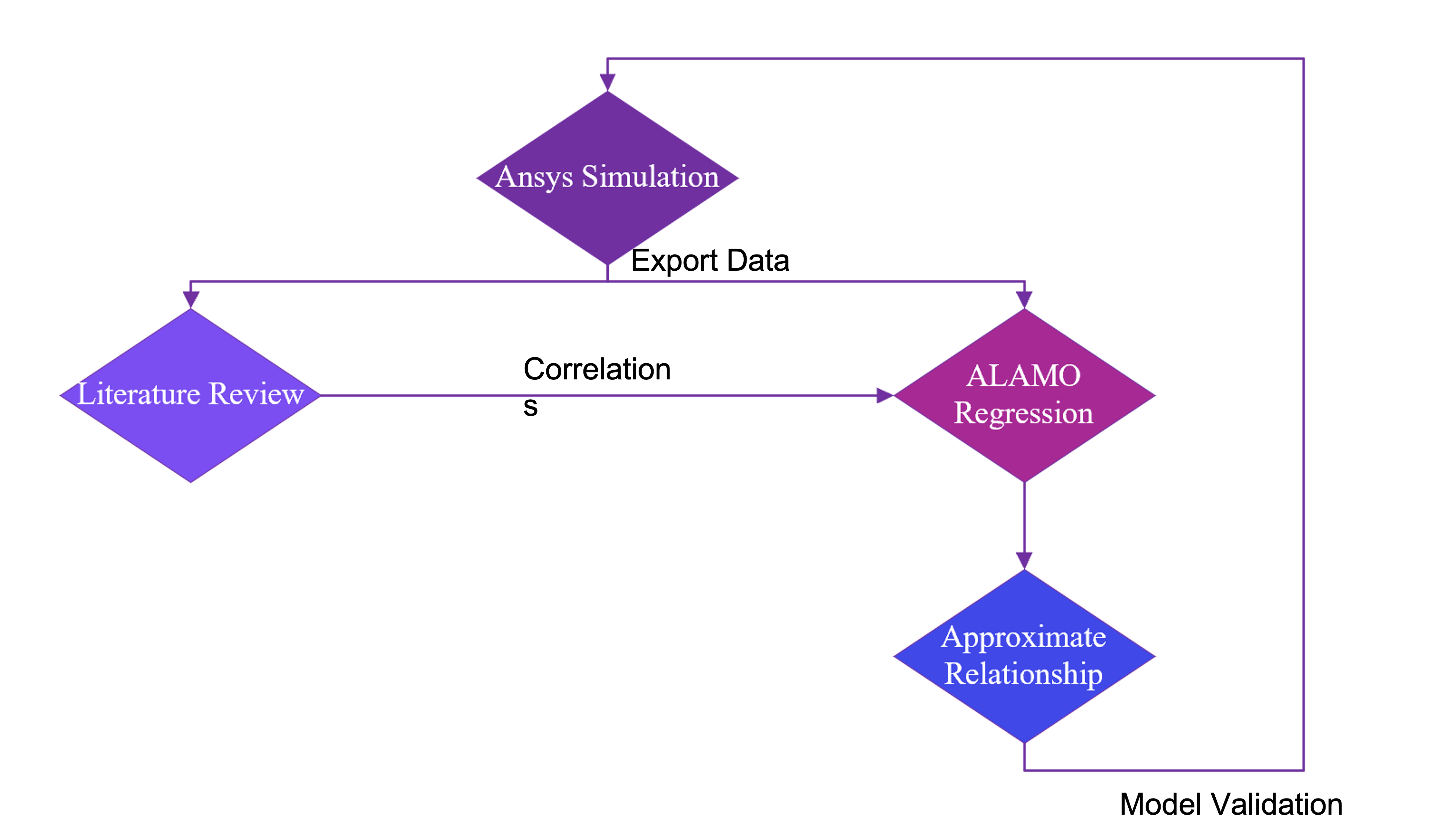

Nel produces hydrogen and innovates its various applications in renewable energy and fuel. Hydrogen is produced via electrolysis which involves splitting water into hydrogen and oxygen. Because this process is not 100 percent efficient, a downstream water-oxygen separator is in place to isolate the unreacted water into a recycle stream back into the electrolyzer. Our project goal is to maximize the efficiency of the separator by manipulating its current design. We used ANSYS Fluent to test different internal and external geometry features to observe their effect on separation efficiency. The team then used ALAMO, a machine learning regression software to obtain a mathematical model of separation efficiency with respect to different geometries, vessel size and other measured variables. Having an efficient separator and an experimentally verified model as a basis for design will allow downstream unit operations to also operate efficiently, minimizing energy and material waste in the process.