This video contains proprietary information and cannot be shared publicly at this time.

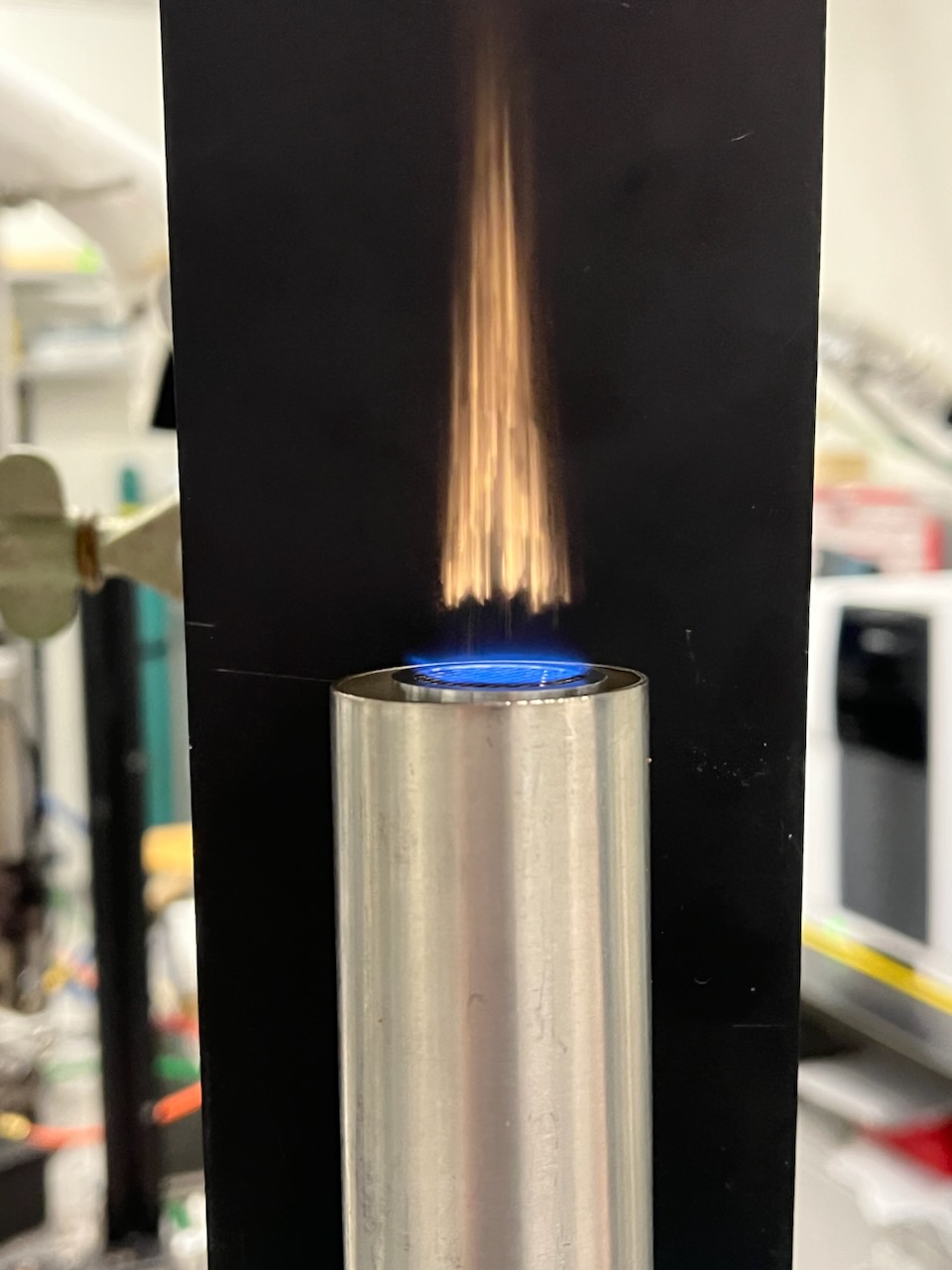

Figure 1

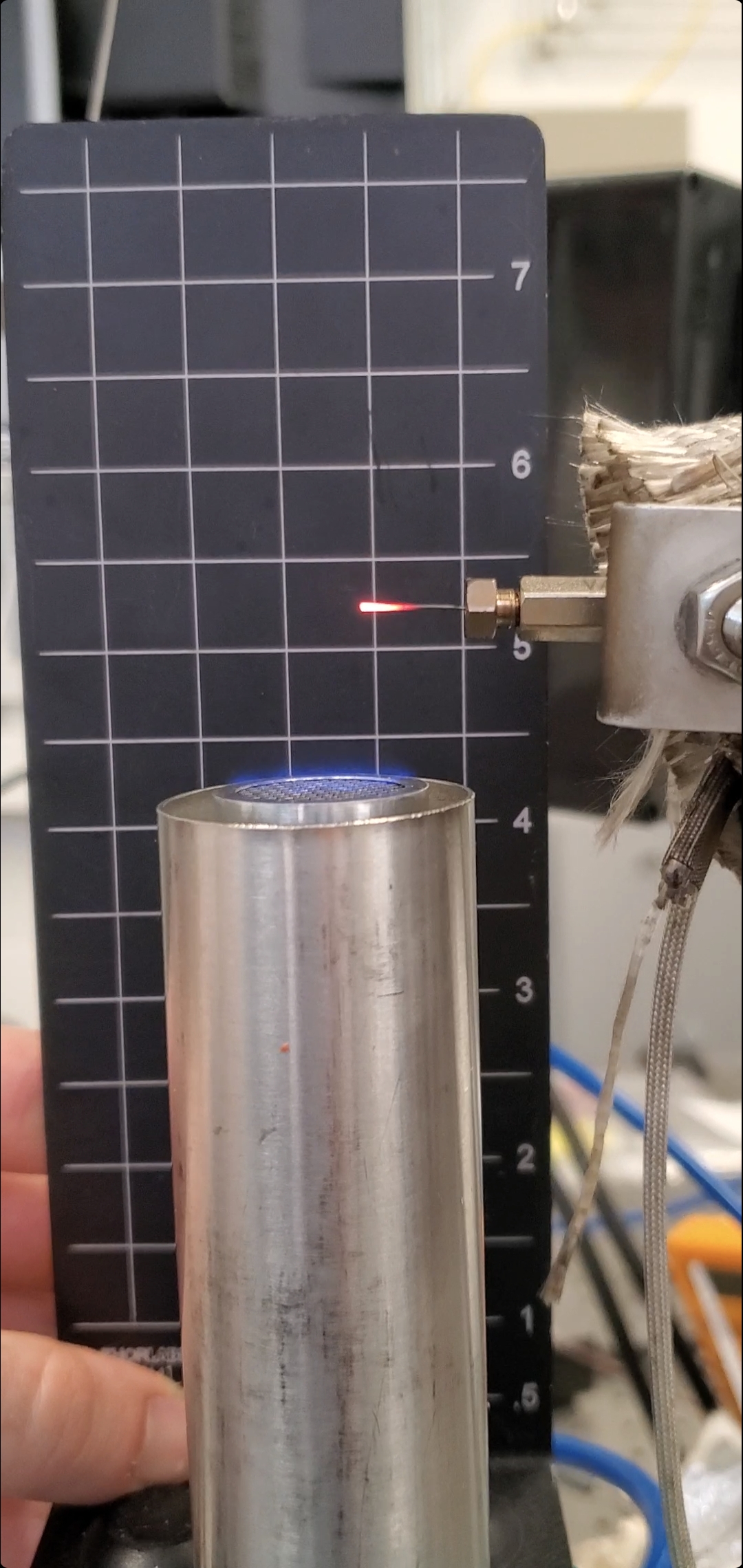

Figure 2

Team 62

Team Members |

Faculty Advisor |

Dylan Errico |

Dr. Francesco Carbone Sponsor UConn School of Engineering |

sponsored by

Developing a Flat Premixed Droplet Seeded Flame (FPDSF) Experimental Facility to Synthesize Catalyst Nanoparticles

Dr. Francesco Carbone’s Flame, Aerosol, and Nanotechnologies (FANTastic) laboratory focuses on the development of sustainable and affordable approaches to alternative energy sources through cutting edge research and innovative technology. The objective of this project was to design and build an experimental facility to synthesize metallic catalyst nanoparticles with external diameters less than 10 nanometers from a droplet-seeded flame. Metallic catalyst nanoparticles are of interest to the FANTastic lab due to their growing applications in the sustainable energy industry. The delivered experimental facility operates around a vibrating orifice aerosol generator (VOAG) and a burner coupling device. The VOAG generates monodispersed, or uniformly sized, micron-scale droplets of a solution containing a compound of a catalyst metal. The aerosol droplets from the VOAG are mixed with combustion reactants and transferred to a flat premixed flame by the burner coupling device. Within the flame, metallic catalyst nanoparticles arise from pyrolysis of the aerosolized solution. The team restored an existing VOAG to working condition and designed and three-dimensionally printed a burner coupling device to interface with existing FANTastic lab gas infrastructure. Numerical simulation of the burner design in Ansys Chemkin was used to ensure the proper construction of a flow-metering panel for reactant gases. A three-dimensionally printed air-redirection manifold was designed and installed on the VOAG to qualitatively verify droplet mono dispersion, while MATLAB was used to analytically estimate the VOAG aerosol droplet diameters. Gas chromatography with mass spectrometry (GC-MS) and a Differential Mobility Analyzer (DMA) were used to analyze the experimental results. The GC-MS was used to characterize the laminar flame. The DMA was used to confirm the successful production of metallic nanoparticles with external diameters less than 10 nanometers.

Our team collaborated with on this project.