This video contains proprietary information and cannot be shared publicly at this time.

Figure 1

Figure 2

Team 5

Team Members |

Faculty Advisor |

Aadil Shahzad |

Dr. Anson Ma Sponsor Unilever |

sponsored by

Redefining How to Process Body Wash: Creating a More Efficient and Agile Supply Chain

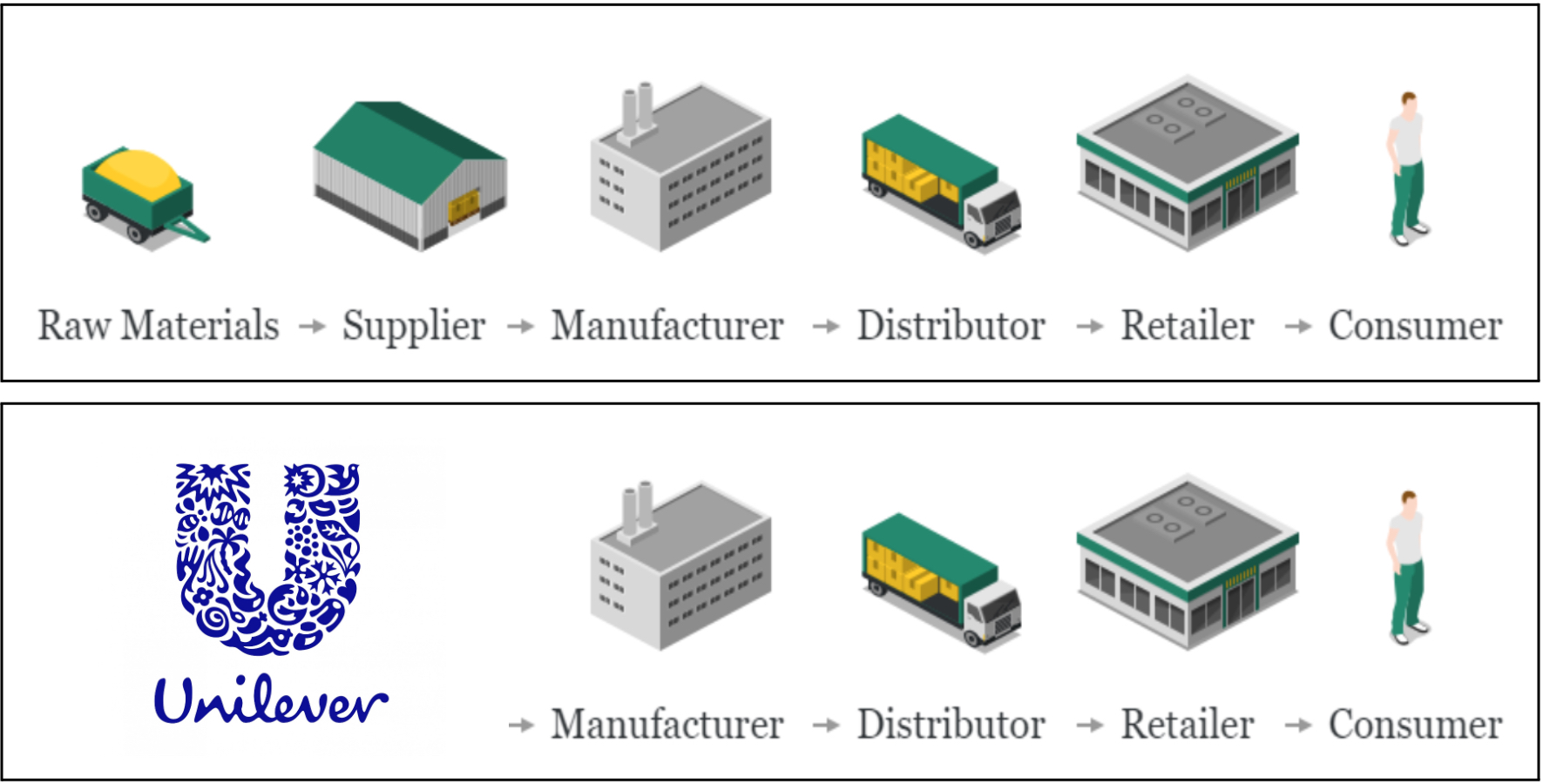

As one of the world’s largest producers of consumer goods, Unilever is constantly seeking solutions to improve their manufacturing processes. Our project aims to develop a standardized protocol for a concentrated body wash that can be diluted internally or by third-party manufacturers. Currently, Unilever makes and ships full formulations to their customers, resulting in a supply chain with limited agility or flexibility. With a concentrate-dilute protocol, the supply chain can streamline their cost structure and manufacture products more efficiently. Beginning at the laboratory scale, our team explored various ratios of surfactants that determine the soaping and cleansing properties of a base Axe body wash formula, and how certain additives modified the fluid flow properties of the developed concentrate. These fluid flow properties, mainly viscosity, were assessed through the use of a rheometer. After determining an optimal concentrate formulation, our team replicated the production process in a pilot manufacturing plant to assess the feasibility of scaling up the formulation. Once the scaled-up product is assessed, a singular protocol will be proposed, detailing how to determine an optimal surfactant ratio and appropriately scale production up. In theory, it will also be applicable to a broad range of product formulations beyond our initial case study. A successful protocol will decrease conversion costs and reduce wasted material while maintaining the product’s desired physical properties and consumer experience. If Unilever can implement this protocol to Axe body washes and other products in their portfolio, they can reinvent their supply chain process and save an estimated $3 million annually.