This video contains proprietary information and cannot be shared publicly at this time.

Figure 1

Figure 2

Team 13

Team Members |

Faculty Advisor |

Andrew Coronel |

Yang Qin Sponsor UConn College of Engineering |

sponsored by

Porous Membranes for Energy Efficient Gas Separation

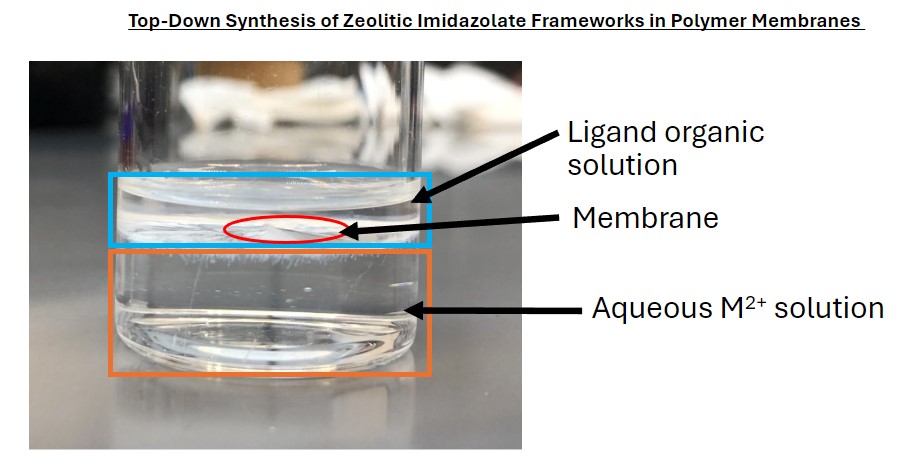

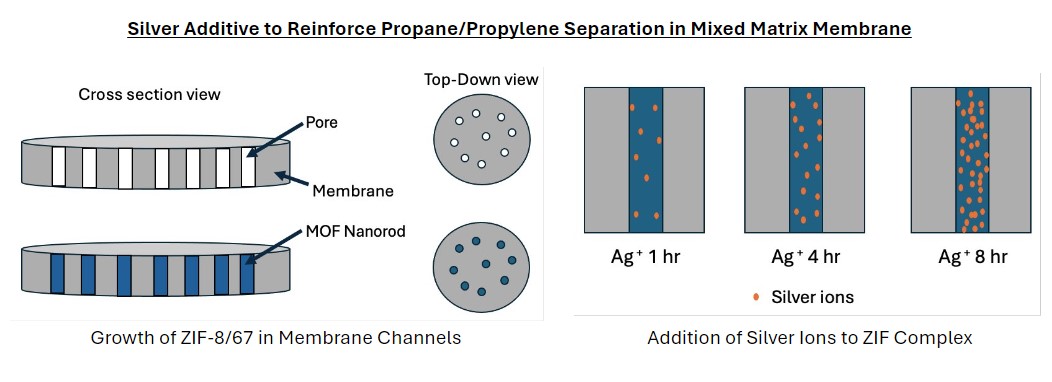

Traditional methods for separating gases, such as cryogenic distillation, require a considerable amount of energy. These energy-intensive processes result in higher energy costs and greater carbon emissions. Despite the costs and emissions, gas separation is an important process because it creates the precursor gases for several products that we use. Propylene is an example of a precursor gas that creates common polymeric materials such as clothing, packaging, and furniture. Using membranes for gas separations is an alternative method that reduces energy costs and emissions. Our team’s objective is to optimize the porous membrane synthesis process to separate gases such as propane and propylene. We grew metal organic frameworks (MOFs) inside the pores of polycarbonate track-etched (PCTE) membranes. MOFs are porous polymers that use metal ions coordinated by organic ligands to create structures with a certain pore size. Specifically, we created a subclass of MOFs called zeolitic imidazolate frameworks (ZIFs), which use imidazolate ligands. For the metal ions in our ZIF structures, we used zinc and cobalt. Our membranes separate gases with a process called molecular sieving, which is when the pore sizes of membranes only allow the smaller molecules to pass through. Additives such as silver and polyvinyl alcohol were included in our syntheses to improve gas separation. We tested the membranes using gas chromatography to see the amount of propylene going through the membrane compared to propane. As climate change becomes an increasing threat, our team believes that porous membranes are the next step for energy-efficient gas separation processes.