This video contains proprietary information and cannot be shared publicly at this time.

Team 02

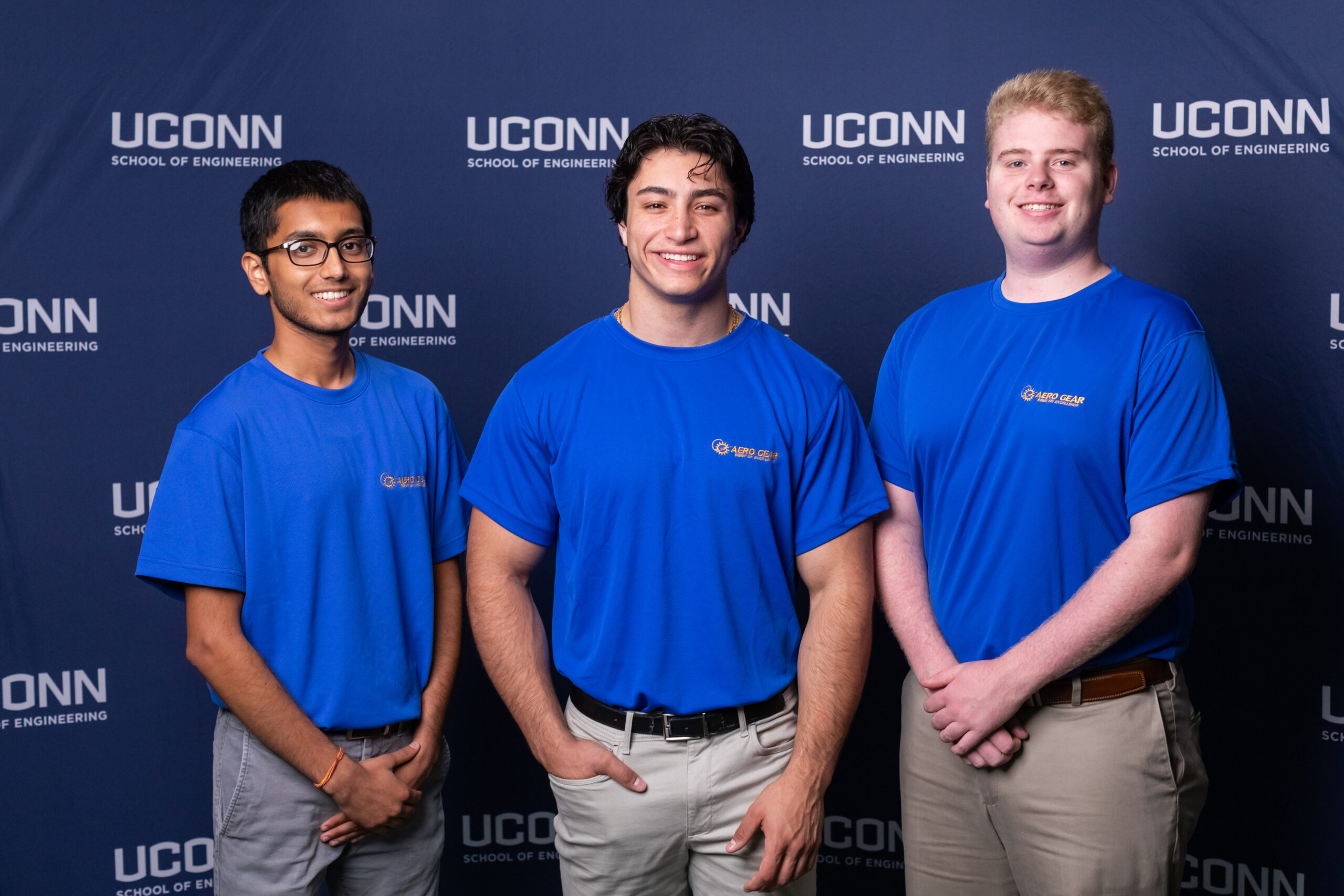

Team Members |

Faculty Advisor |

Aditya Awasthi |

Ryan Cooper Sponsor Aerogear |

sponsored by

Sponsor Image Not Available

Process and Tooling for Uniform Spiral Bevel Gear Finishing

Aero Gear provides a superfinishing process to their gears in order to increase efficiency and power provided. The project’s fixture will be attached to their spiral bevel gear during the superfinishing process, which consists of parts moving through a tumbler filled with ceramic material. The material polishes and smoothens the exposed part surfaces; the fixture will expose the gear teeth and protect the rest of the part. Aero Gear currently subjects their straight-cut gears to superfinishing and plans to extend superfinishing into their spiral bevel gear production process. This project provides the design, manufacture, and testing for a 3D printed fixture device to be used for superfinishing processes. The fixture will be implemented on Aero Gear’s spiral bevel gears and will expose the gear teeth to superfinishing while protecting all other surfaces of the gear. The fixture must rotate in a specific manner in the tumbler during the superfinishing process to properly remove material from the gear flanks. The required size and shape of the fixture to induce this motion, as well as the motion required are unknown. The ideal size(s) and shape(s) of the ceramic media and the frequency range of tumbler operation to facilitate spiral bevel gear superfinishing are unknown.