Figure 1

Computer Science and Engineering

Team 17

Team Members |

Faculty Advisor |

Xuan Chau |

Dong-Guk Shin Sponsor Unilever |

sponsored by

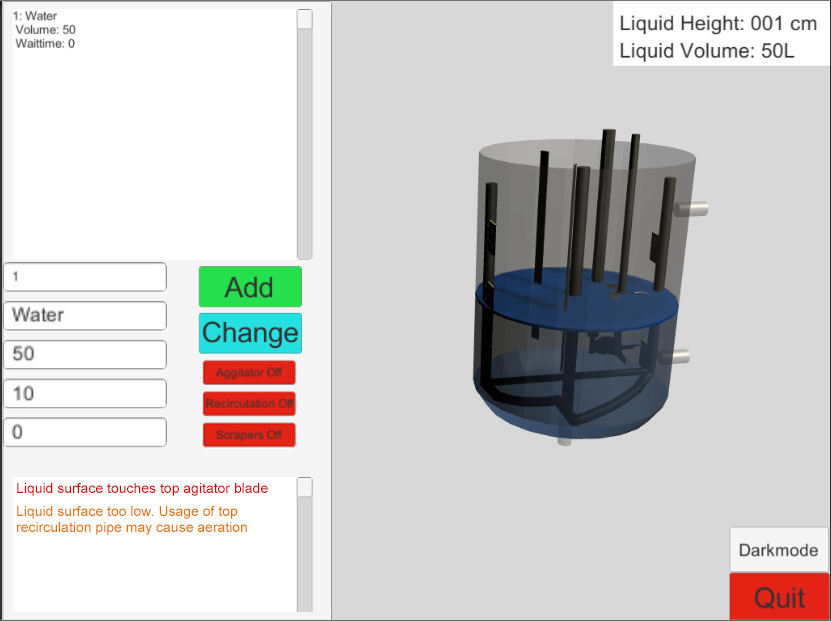

Unilever is a global consumer goods company with over 300 factories worldwide, and produces a variety of personal care products. The company oversees ingredient-mixing operations in large-scale production tanks of varying sizes and configurations. Unilever’s Research and Design teams are constantly creating and testing new products, whose production must be scaled to fit a production-sized environment. This is a complicated and risky process due to several risk factors associated with large-batch mixing. Namely, the vertical height of the liquid must not fall in any “critical points” found within the tank, which would ruin, aerate, or otherwise reduce the quality of the product. The goal of this project is to create a web-based, Unity 3D process visualization tool that allows Unilever’s researchers to accurately observe and predict mixing conditions in a virtual environment. The tool automates critical point checks and volume calculations, while offering a transparent view of the tank. By connecting to Unilever’s SQL tank database, the app is capable of accurately modeling any tank that is tracked. Through a simple UI, users can add, remove, and change steps in their theoretical mixing process, while receiving crucial feedback on the state of the mixture.