This video contains proprietary information and cannot be shared publicly at this time.

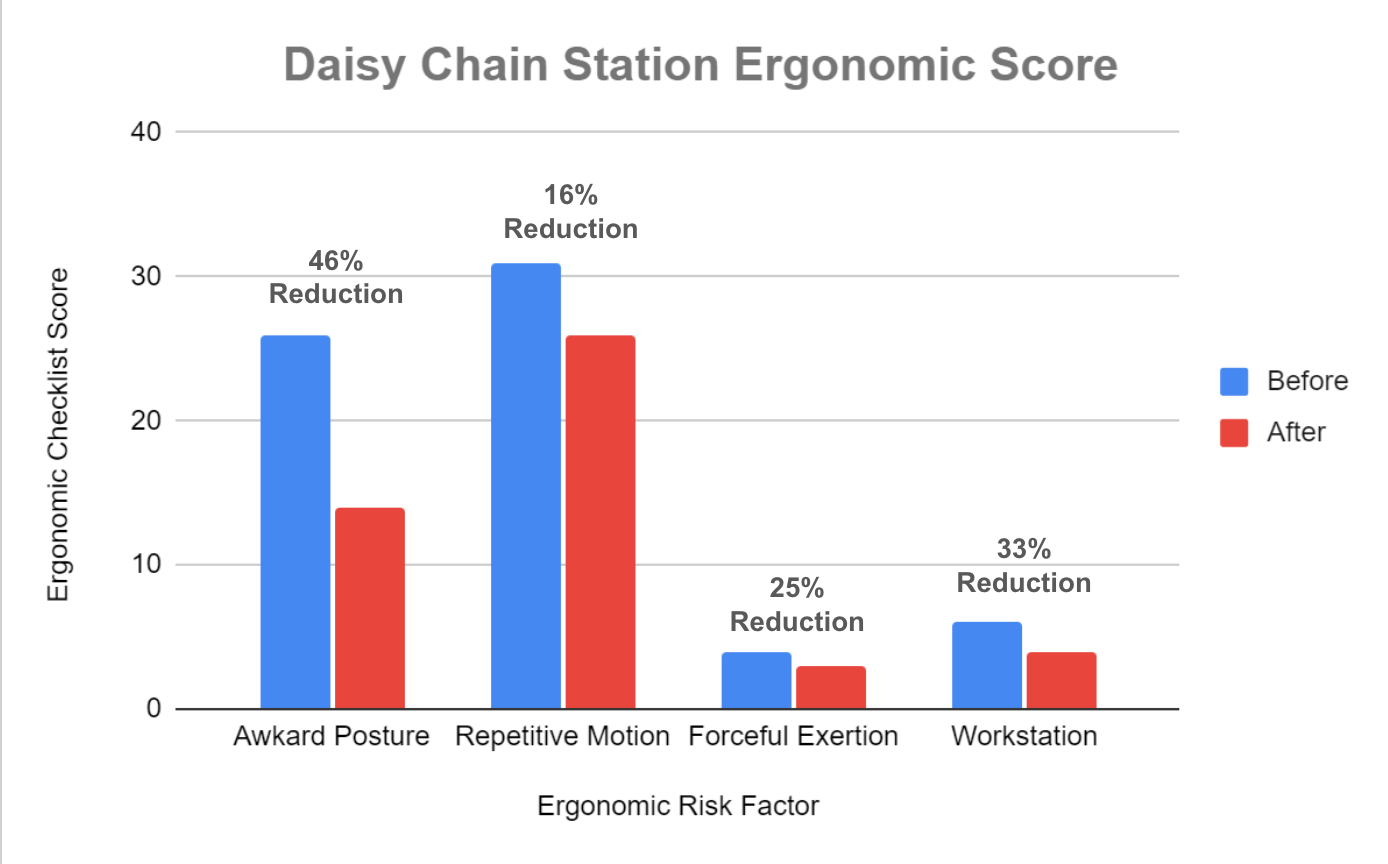

Figure 1

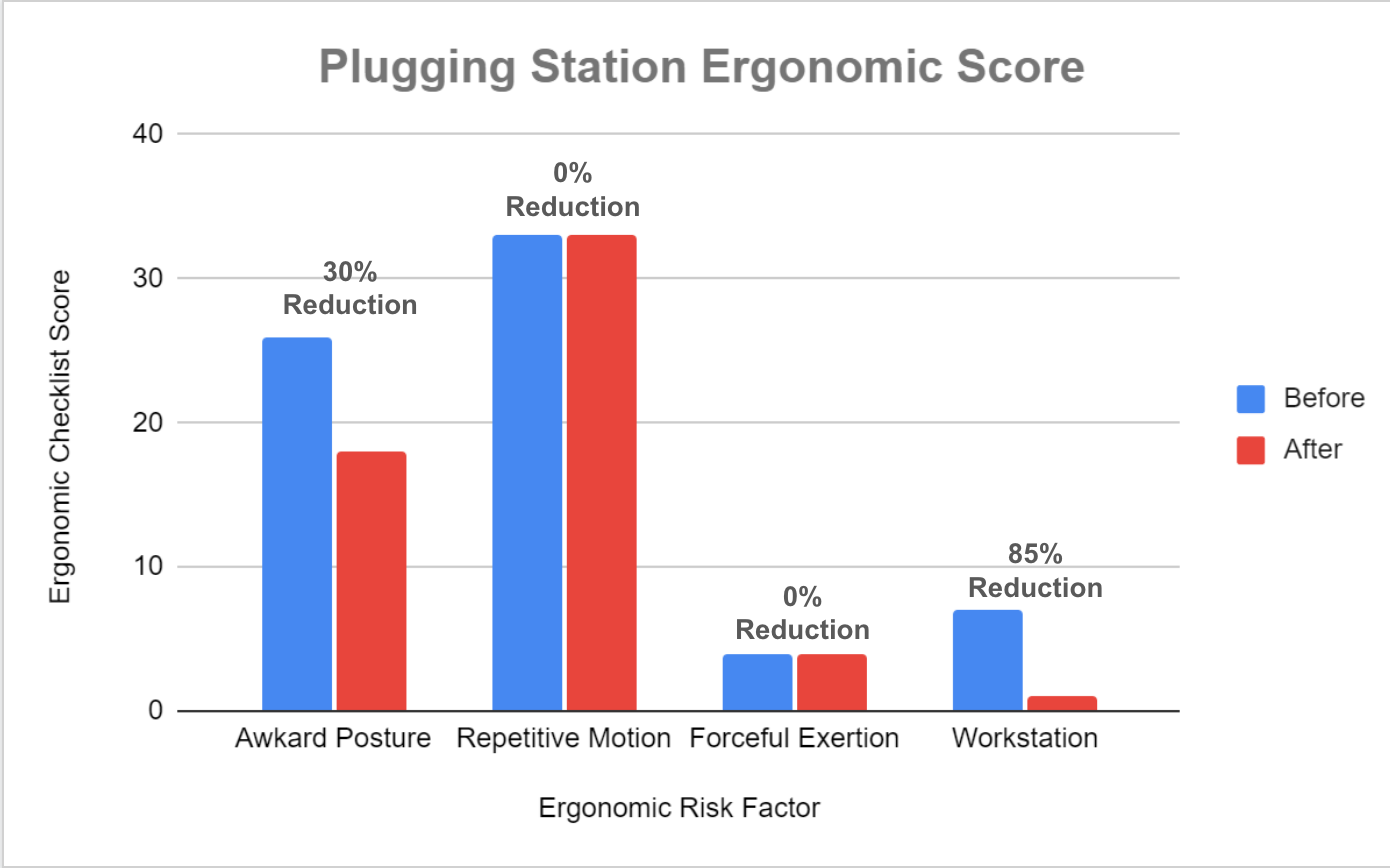

Figure 2

Team 11

Team Members |

Faculty Advisor |

Natiya Washer |

Frank Cunha, Craig Calvert Sponsor Other |

sponsored by

Prysmian Group added a new assembly process about four years ago, since then the volume of that assembly has increased 300%. As the assembly line grew so did the concern for the health of the employees. The most pressing concern is ergonomic issues leading to soft tissue injuries. As a result, Prysmian reached out to Uconn to address their ergonomic concerns. The project consists of diagnosing the largest contributors to ergonomic risk factors and tailoring solutions to reduce them. Ergonomic checklists and surveys determined the two workstations containing the most ergonomic risks are the “Daisy Chaining” station and the “Plugging” station. Through root cause analysis at the stations, tailored and custom solutions were identified. To reduce the strain on the most ergonomically at risk parts of the body, new tooling and chairs were purchased. For the Plugging station, a new workstation was designed and built. This workstation is adjustable in both height and angle allowing workers to keep their bodies in more neutral positions than previously. Once the solutions were implemented, the ergonomic risk assessment was repeated to analyze the change in risk factors. There was a significant decrease in ergonomic risk factors for both stations. Finally, a business cost analysis estimates that the ergonomic solutions will lead to an annual savings of over $100,00 dollars and have a payback period of less than a year. Prysmian Group is pleased with the results of the project and is looking forward to keeping their partnership with UConn in the future.