Figure 1

Team 3

Team Members |

Faculty Advisor |

Samuel Degnan-Morgenstern |

Kelly Burke Sponsor Dymax |

sponsored by

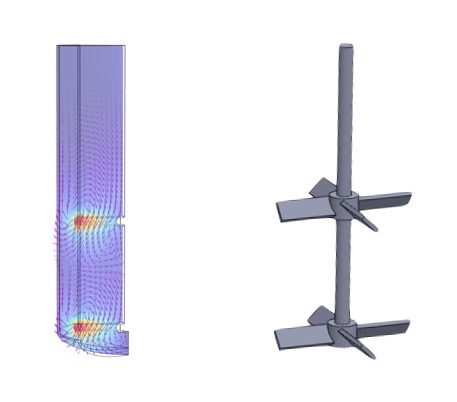

Modeling Mixing Dynamics Across Multiple Stirred Batch Reactors

Bomar, a supplier of oligomeric materials to coating and adhesive applications, utilizes a variety of production-scale and lab-scale continuously stirred batch reactors for the synthesis of these oligomeric products. During the operation of these reactors, controlling the impeller speed is critical to maintaining repeatable reaction dynamics, ensuring product quality, and achieving desired batch cycle times. The mixing dynamics in the reactors are not uniform between reactors, and mixing speeds are currently set using empirical guidelines instead of being theoretically modeled. This may be contributing to unnecessary increases in production times, utility costs, and first pass yield issues. The goal of our project is to develop a model-backed approach to characterize the mixing dynamics and determine the minimum agitator setting to achieve thorough and consistent mixing when scaling across reactors. To solve this problem, we first modeled the Bomar reactor and impeller geometries using SOLIDWORKS. Using these designs, we performed simulations of mixing dynamics in COMSOL for a variety of reactor geometries, baffle and agitator designs, and product viscosities. Based on the results of these simulations, we created a database for each reactor that specified the minimum agitator setting necessary for each product viscosity. This guide will ensure consistent reaction conditions, reduce utility costs, and aid in a more repeatable scale-up process from the laboratory scale to the production floor.