Figure 1

Figure 2

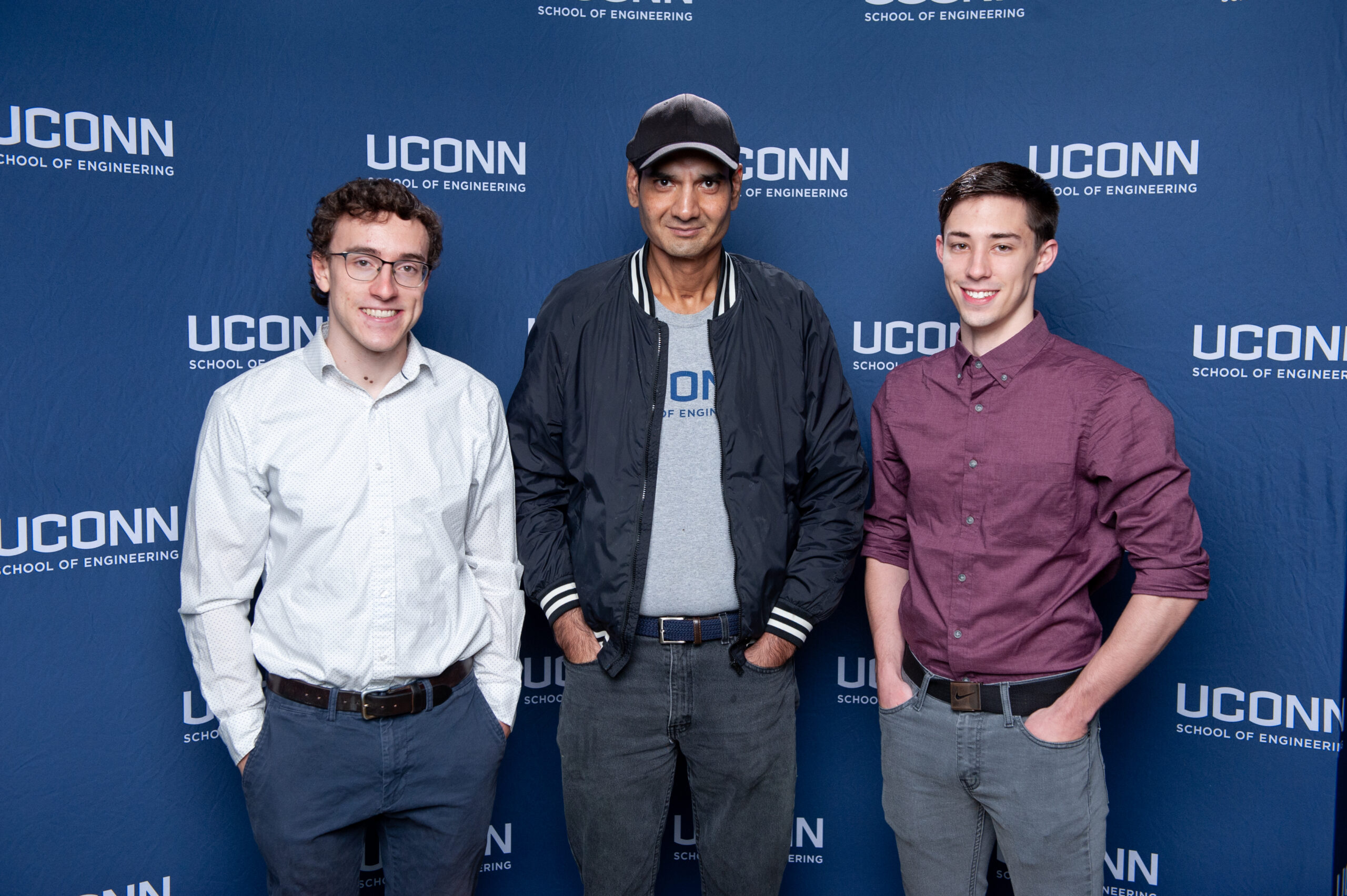

Team 09

Team Members |

Faculty Advisor |

Elliot Bushman |

Jason Lee Sponsor Other |

sponsored by

Pickup and Stacking Device for Flat Spring Production

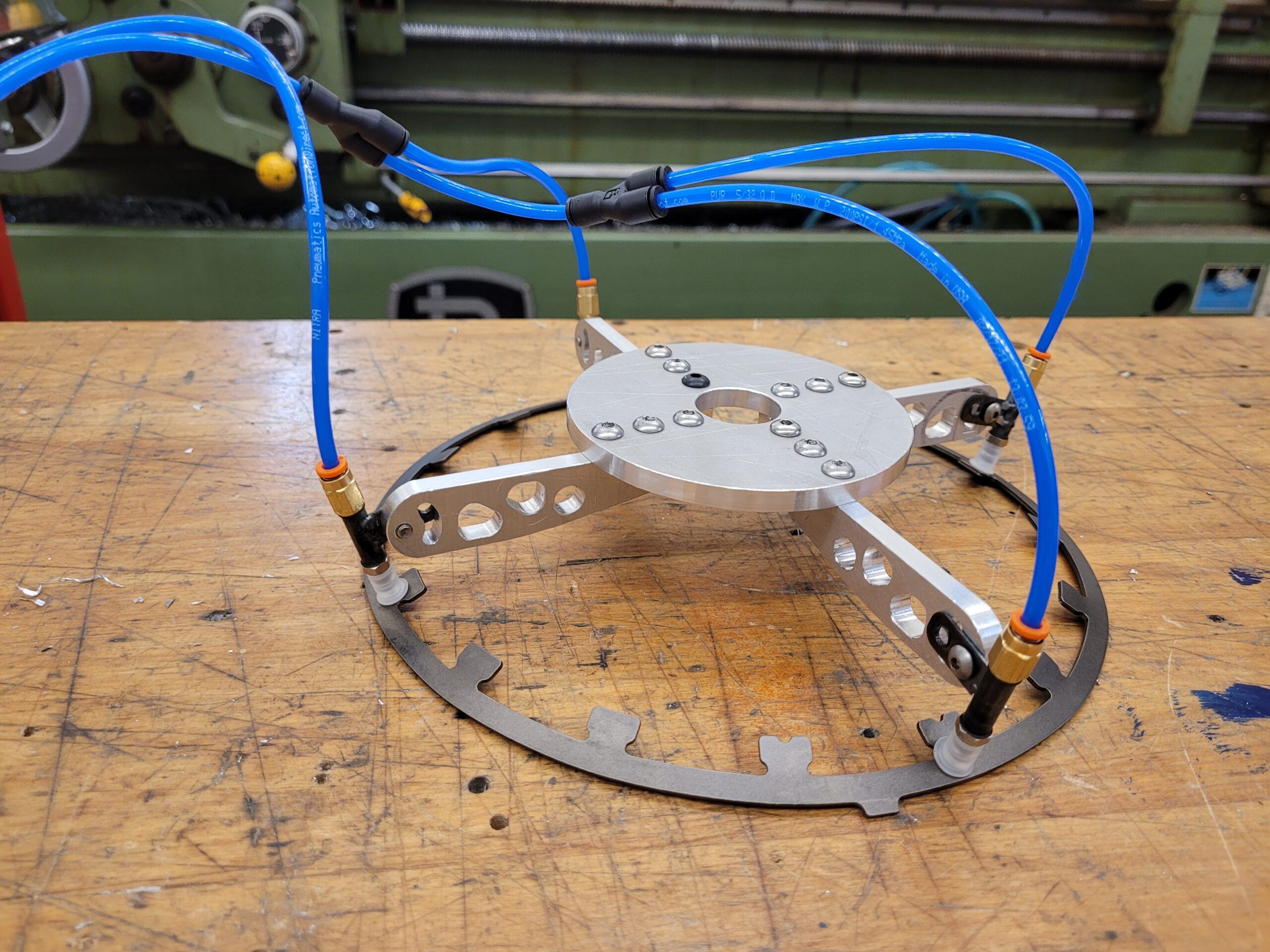

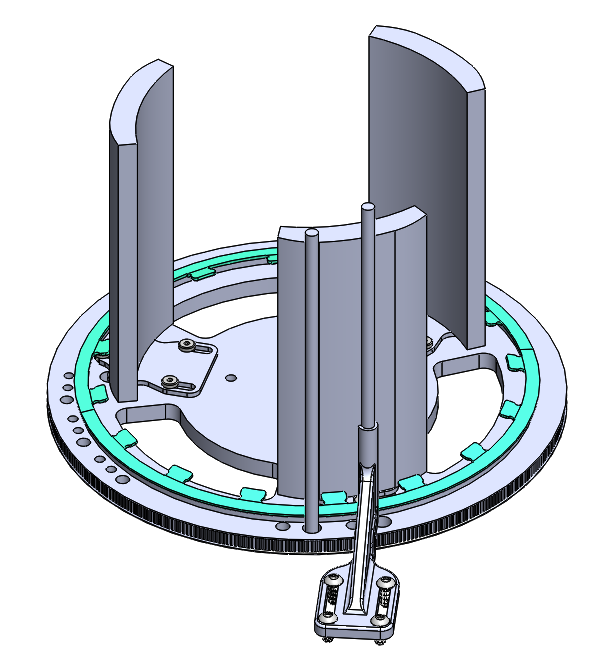

Barnes is a manufacturer of a wide range of springs, with their Connecticut facility handling flat and stamped varieties. One of their products includes the Belleville spring washer which is used in clutches in the automotive industry. As a part of the quality assurance process each spring undergoes a load-deflection test, to make sure that spring rate falls within acceptable industry standard. Currently loading of Belleville washer spring into the test machine is achieved manually, which is labor intensive and time consuming. Barnes is considering the use of a robot arm to automate the testing process, thus reducing labor costs. The objective of this project is to develop end of arm tooling to allow robotic arms to easily pick up and manipulate parts into and out of test fixtures. Due to the size and complex geometry of the Belleville washer, as well as the tight clearances of the test fixtures a universal pickup mechanism would not be sufficient. By designing and building custom end of arm tooling we will be able to increase the function and reliability of the robotic arm, increasing capacity and decreasing operator intervention. Our tooling has two components, a device to orient a stack of washers to fit into the fixture and another to pick up and manipulate washers.