This video contains proprietary information and cannot be shared publicly at this time.

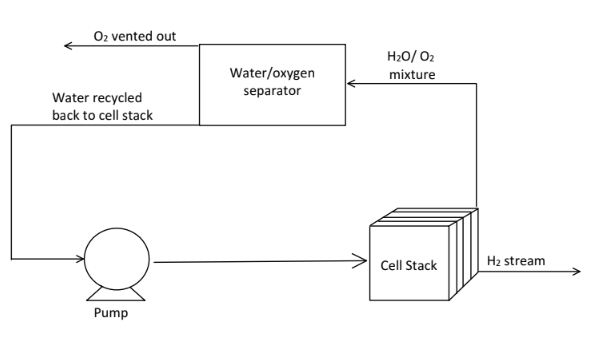

Figure 1

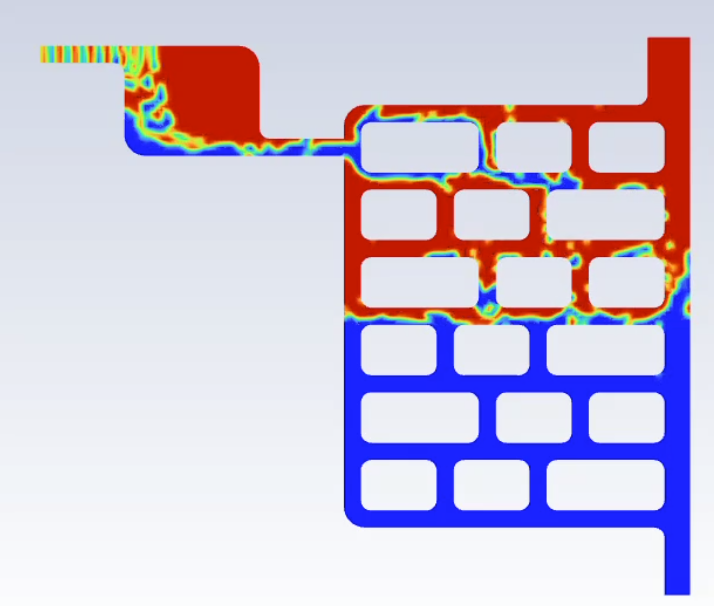

Figure 2

Team 5

Team Members |

Faculty Advisor |

Robert Quizani |

Dr. George Bollas Sponsor Nel Hydrogen |

sponsored by

Sponsor Image Not Available

Optimizing Water and Oxygen Phase Separation in Electrolyzers with T-Junction Technology

As we shift away from a carbon economy, hydrogen energy is emerging as a viable alternative energy form. Nel Hydrogen creates electrolyzers that produce hydrogen by splitting H2O into hydrogen and oxygen molecules through a process known as electrolysis. It yields a stream with liquid water and gaseous oxygen, and a separate stream of pure hydrogen. The liquid water enters an outlet stream because not 100% of the water splits into hydrogen and oxygen. The hydrogen stream can then be used, transported, or stored as a potential energy source. Pump cavitation is an undesired condition where gaseous bubbles enter pumps and potentially collapse or implode when they encounter regions of higher pressure. Pump cavitation causes intense localized forces on pump components, resulting in erosion, pitting, and structural damage to the pump. To prevent pump cavitation, we are simulating T-junction designs to separate the oxygen and water into different outlet streams using ANSYS Fluent software. By adjusting factors like velocity, tank length, and inlet and outlet diameters, we can conduct a sensitivity analysis. By manipulating variables, we can optimize the performance of the separator. By improving the separation efficiency, we can reduce the necessary inlet deionized water, reducing electrolyzer operating costs. This optimization will also improve the longevity and compactness of the electrolyzers. This project contributes to the ever-advancing landscape of green hydrogen energy as a step towards reducing our global carbon footprint.